Andy, returning to your stream tube question, and intake area ratio...

First establish known parameters. For this example we'll assume that we're climbing at 120 KTAS through 2000 feet on a standard day, and mass flow (from the Lycoming cooling chart) is expected to be 2.4 lbs per second.

120 KTAS = 202.53 feet per second

2.4 lbs per second / 2 inlets = 1.2 lbs per second per inlet

Standard density 2000 ft = 0.072098 lbs per cubic foot

1.2 lbs / 0.072098 = 16.6440 cubic feet

The necessary math is based on the usual formula for volume:

volume = area x length

or

volume = radius^2 x pi x length

We know the length of the stream tube (202.53 feet) and the volume (16.6440 cu feet), so just flip it around and solve for R^2:

volume / pi x length = R^2

16.6440 / 3.14 x 202.53 = 0.02617

That's radius squared, so its square root is the actual radius of the stream tube...

sqrt of 0.02617 = 0.1618 feet

Two times radius is diameter, so:

0.1618 x 2 = 0.3236 feet

And last, 0.3236 x 12 = 3.8832 inches stream tube diameter for one intake.

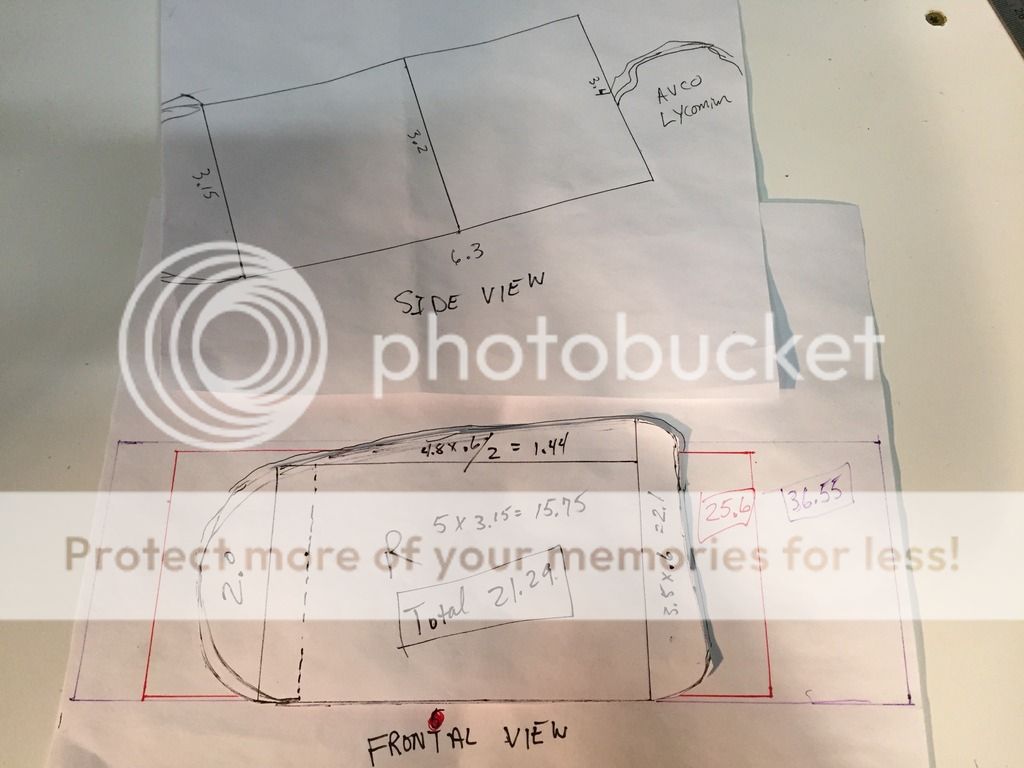

We're interested in area ratio, i.e. stream tube diameter / intake diameter, so we need area for each. Here I'll assume a 6" diameter inlet ring, since I don't yet know what you might choose:

(3.8832 / 2)^2 x 3.14 =11.837 sq in

(6 / 2)^2 x 3.14 = 28.26 sq in

11.837 / 28.26 = 0.4188 area ratio, which is the same as Vi/Vo

Yes, I've put it into a spreadsheet and sent it to you.

Plug in different altitudes and airspeeds. You'll see that Vi/Vo changes with each change of input. For example, at 175 KTAS the stream tube is longer for the same volume, so diameter is decreased, and area ratio becomes 0.2871.

Take particular note of the converse; area ratio rises when airspeed is reduced. It means for a high Vi/Vo inlet, low airspeed makes diffuser quality more critical...which is why some small inlets don't cool very well at low speed and high AOA. Any little design error or condition that pushes the inlet flow into separation tanks the Cpu value.

As always, ya'll check my arithmatic