PaulvS

Well Known Member

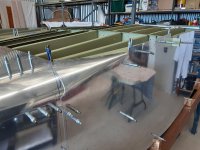

A younger version of me started this slow build RV-6A just after Oshkosh '92. I completed the empennage and wings in my spare time and got started on the fuselage. Then other things in life took priority and the RV project went on hold for 21 years.

We've moved house a few times and the fuselage frame had to come out of the jig for the most recent shift. I'm now getting the workshop organised and ready to start building again.

Back in '92 there were only three RV models to choose from. And Van's was just talking about quick build kits. The plans are hand drawn and the only factory made holes were in the wing spar. The new kits look way easier and it would probably be quicker to assemble a new project than to finish this old one, but I kinda like this orphan relic from the 90's!

We've moved house a few times and the fuselage frame had to come out of the jig for the most recent shift. I'm now getting the workshop organised and ready to start building again.

Back in '92 there were only three RV models to choose from. And Van's was just talking about quick build kits. The plans are hand drawn and the only factory made holes were in the wing spar. The new kits look way easier and it would probably be quicker to assemble a new project than to finish this old one, but I kinda like this orphan relic from the 90's!

Last edited: