ChiefPilot

Well Known Member

One of the things I had seen on a couple of RVs at Oshkosh a while back was a hidden hinge & latch system for the oil door on the top cowling. I knew that I wanted this on my RV, and so as I was proceeding with the build I kept thinking about how I would do this. I had several requirements:

I think I met these goals; this is the final result:

I first started by cutting away the opening in the top cowl. Although the plans called for some material to be left on the lower left & right corners, I trimmed this away as the latch mechanism did not need it and it would only get in the way. The door fit pretty well, supported by an approximately 3/4" flange.

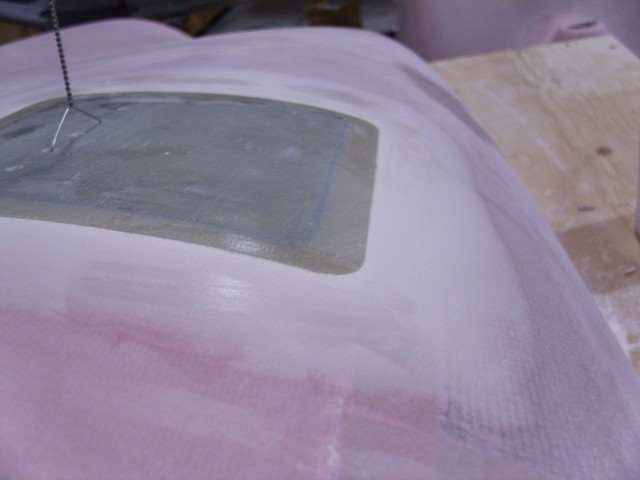

Next up was some body work to make the door fit nicely into the opening. Van's cowl was close, but not quite good enough plus I wanted round corners on the door which mean at least some filler would need to be used. I rounded the corners of the door with a sanding block and prepped the top cowling to receive some micro. I then wired the door into place by drilling some holes through the door, running safety wire through then around a piece of angle that clamped the door to the cowl, then back out. Micro was applied and this is what it looked like:

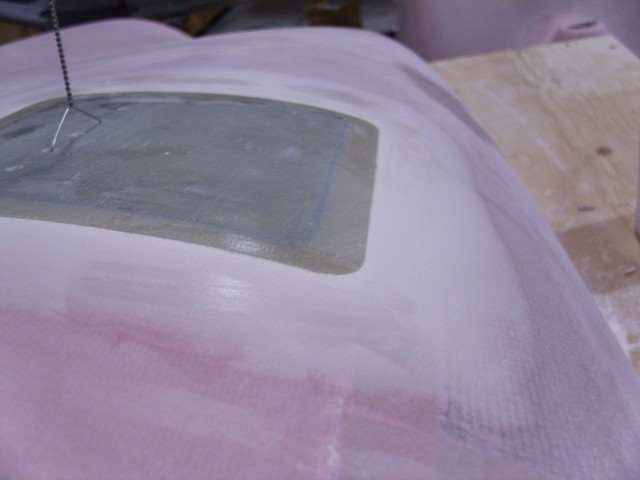

After letting it cure a couple of days, it was time to hit it with the sanding block to produce a smooth finish:

When it came to the hinge, I tried several approaches. I tried a hinge made from .032 aluminum and fastened to the edge of the door. This was far too flexible; not only did it allow the door to move easily but it also did nothing to stiffen the door to prevent it from bulging out in flight. I next tried .040 aluminum and found that while it was stiffer, it still did nothing to stiffen the door. At this point, I think I read one of Dan Horton's pearls of wisdom about carbon fiber and decided to give that a go. I made a prototype hinge out of 0.020 aluminum to get the geometry correct, then used it as a form for laying up three layers of 8oz carbon fiber. I am extremely happy with this approach and how it turned out. It's much stiffer than either of the aluminum approaches I tried, and since it fastens to the door in the center vs. an edge, there is much less tendency for the door to flex or bow in the middle.

The latching mechanism was the next piece of the puzzle. I had seen a latch at Aircraft Spruce but it was big, heavy, and somewhat expensive. Other latches I looked at seemed too small or prone to failure. A failed latched was something I gave some thought to, since if I couldn't open the oil door I wouldn't be able to easily remove the cowl. In the end, I made my own latch from a piece of UHMW, a 5/16th" stainless steel rod, a spring, a roll pin, and a brass tube.:

The UHMW acts as a frame for the pin. The stainless steel pin slides inside the brass tube, with a roll pin acting as both a stop and the driving surface for the spring. The hole in the UHMW in which the brass tube lives is slightly countersunk on either end and the brass tube itself is slightly flared on either end. The end of the stainless steel rod was machined down to a thickness appropriate to a clevis on the pull cable.

The UHMW acts as a frame for the pin. The stainless steel pin slides inside the brass tube, with a roll pin acting as both a stop and the driving surface for the spring. The hole in the UHMW in which the brass tube lives is slightly countersunk on either end and the brass tube itself is slightly flared on either end. The end of the stainless steel rod was machined down to a thickness appropriate to a clevis on the pull cable.

I mounted the latch on the top cowling using some layups of fiberglass to hold it in place. The fiberglass covers either side of the latch, and two 8/32 socket head screws extend through the fiberglass and UHMW to secure the latch in place.

When the door is closed, the pin engages a receptacle on the oil door made from brass tubing and affixed to the door with flox and fiberglass. I installed the hinge on the door and mounted the door to the top cowl, then taped it shut. The receptacle is somewhat longer than needed, and was squeezed flat on one end. Additionally, several holes were drilled in the far to to provide an additional mechanical hold for the upcoming epoxy/flox mix. I greased the pin appropriately, slipped the receptacle on, and built up the area underneath and around the receptacle with the epoxy/flox mix. Once dry, I layered some FG cloth over it to secure it.

...continued

- Only visible artifact on the oil door would be it's outline.

- Must be strong i.e. oil door should not be flexible to bend outward in flight.

- Must be able to open oil door while standing in front of it i.e. I didn't like the idea of a cockpit-controlled oil door release.

I think I met these goals; this is the final result:

I first started by cutting away the opening in the top cowl. Although the plans called for some material to be left on the lower left & right corners, I trimmed this away as the latch mechanism did not need it and it would only get in the way. The door fit pretty well, supported by an approximately 3/4" flange.

Next up was some body work to make the door fit nicely into the opening. Van's cowl was close, but not quite good enough plus I wanted round corners on the door which mean at least some filler would need to be used. I rounded the corners of the door with a sanding block and prepped the top cowling to receive some micro. I then wired the door into place by drilling some holes through the door, running safety wire through then around a piece of angle that clamped the door to the cowl, then back out. Micro was applied and this is what it looked like:

After letting it cure a couple of days, it was time to hit it with the sanding block to produce a smooth finish:

When it came to the hinge, I tried several approaches. I tried a hinge made from .032 aluminum and fastened to the edge of the door. This was far too flexible; not only did it allow the door to move easily but it also did nothing to stiffen the door to prevent it from bulging out in flight. I next tried .040 aluminum and found that while it was stiffer, it still did nothing to stiffen the door. At this point, I think I read one of Dan Horton's pearls of wisdom about carbon fiber and decided to give that a go. I made a prototype hinge out of 0.020 aluminum to get the geometry correct, then used it as a form for laying up three layers of 8oz carbon fiber. I am extremely happy with this approach and how it turned out. It's much stiffer than either of the aluminum approaches I tried, and since it fastens to the door in the center vs. an edge, there is much less tendency for the door to flex or bow in the middle.

The latching mechanism was the next piece of the puzzle. I had seen a latch at Aircraft Spruce but it was big, heavy, and somewhat expensive. Other latches I looked at seemed too small or prone to failure. A failed latched was something I gave some thought to, since if I couldn't open the oil door I wouldn't be able to easily remove the cowl. In the end, I made my own latch from a piece of UHMW, a 5/16th" stainless steel rod, a spring, a roll pin, and a brass tube.:

I mounted the latch on the top cowling using some layups of fiberglass to hold it in place. The fiberglass covers either side of the latch, and two 8/32 socket head screws extend through the fiberglass and UHMW to secure the latch in place.

When the door is closed, the pin engages a receptacle on the oil door made from brass tubing and affixed to the door with flox and fiberglass. I installed the hinge on the door and mounted the door to the top cowl, then taped it shut. The receptacle is somewhat longer than needed, and was squeezed flat on one end. Additionally, several holes were drilled in the far to to provide an additional mechanical hold for the upcoming epoxy/flox mix. I greased the pin appropriately, slipped the receptacle on, and built up the area underneath and around the receptacle with the epoxy/flox mix. Once dry, I layered some FG cloth over it to secure it.

...continued

Last edited: