Capt. Tyler Voss went down May 3 2013 in a KC-135. Before he deployed he and I got together to re-vamp his tired RV.

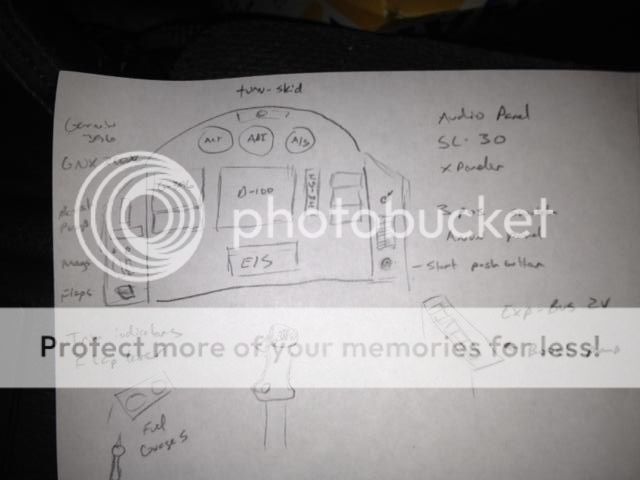

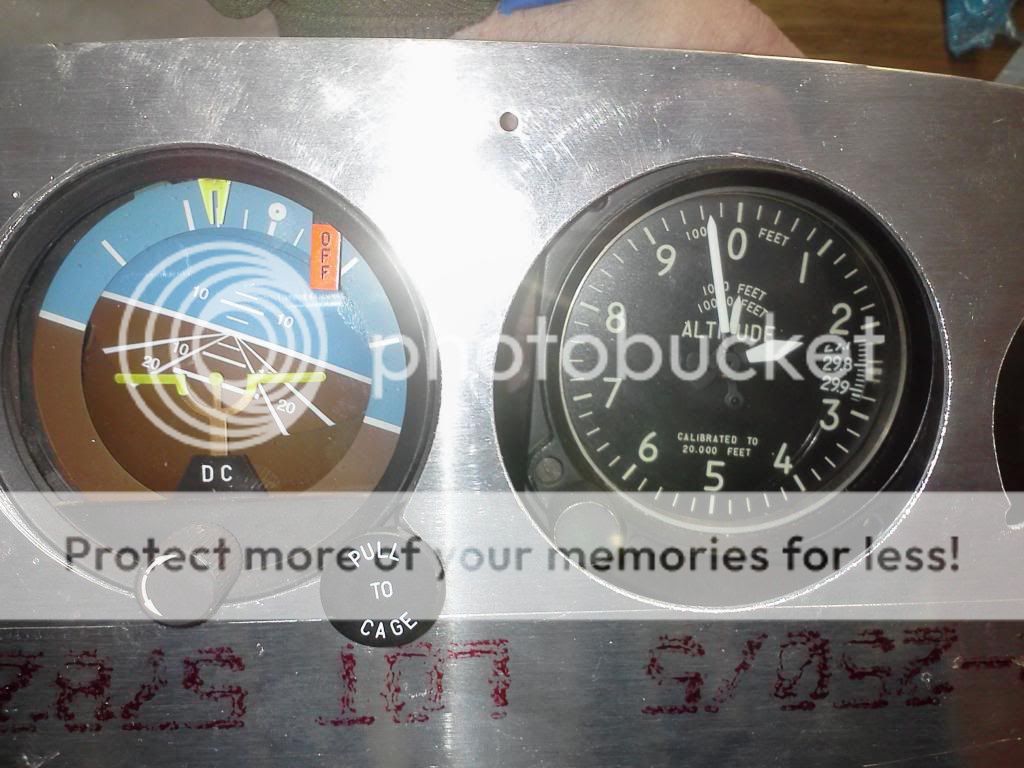

I teach Electrical & Environmental systems on the tanker, he came through a class of mine when he approached me with the offer. He wanted all the wiring done and was not comfortable with doing it himself. That is where I came in. his plan was to strip it all down and repaint many parts and add new systems.

We flew it a few times before we parked it for the overhaul (I think he did it to get me sold on the idea if you ask me) haha, but he did not need to, i was already bitten by the RV bug!

When Tyler went down with the rest of his crew, I felt I had to finish the project no matter how long it took.

I wanted to document all that I have done.

Just to let you guys know.. I am not an A&P, just been an Aircraft electrician with the AF for about 7 years and a commercial Electrician for the past 12 years before enlisting.

I have been reading many articles on how things are done, different techniques and such to finish it up.

I have had an abundance of help from chapter EAA 79 Spokane where the plane is currently located.

Please feel free to comment and make suggestions as I am new at the aircraft fabrication field.

Last edited: