LettersFromFlyoverCountry

Well Known Member

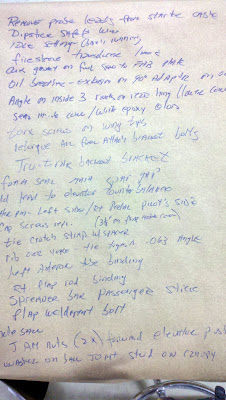

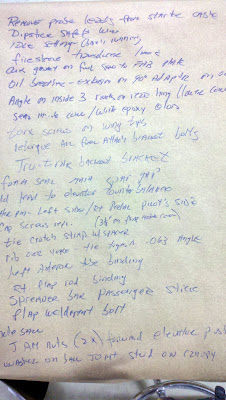

There it is:

that's the list of squawks found on my RV-7A project by two of the most legendary RV specialists on Planet RV today -- Tom Berge and Doug Weiler.

I post this because in the EAA thread, someone pointed out how valuable RV builder groups are. This is a great example. Two guys gave up their Sunday afternoons to help another builder get his plane ready for the DAR.

And they've done this so many times and they know the DAR so well -- he's also an RV builder -- that I have to believe just knowing that these guys have already looked at the bird, will make his job much easier.

I've got the bigger image of the squawks on the blog, and some notations we made -- and also a link to the audio interview I did with Tom on tips for building RVs.

Two great guys doing great work for RV builders.

that's the list of squawks found on my RV-7A project by two of the most legendary RV specialists on Planet RV today -- Tom Berge and Doug Weiler.

I post this because in the EAA thread, someone pointed out how valuable RV builder groups are. This is a great example. Two guys gave up their Sunday afternoons to help another builder get his plane ready for the DAR.

And they've done this so many times and they know the DAR so well -- he's also an RV builder -- that I have to believe just knowing that these guys have already looked at the bird, will make his job much easier.

I've got the bigger image of the squawks on the blog, and some notations we made -- and also a link to the audio interview I did with Tom on tips for building RVs.

Two great guys doing great work for RV builders.