Van's Air Force

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Car Alternator for Lycoming O-360?

- Thread starter GalinHdz

- Start date

John Clark

Well Known Member

Actually, the Van's supplied alternator is a 60A unit from a Suzuki Samari, made by Nippon Denso.

John Clark ATP, CFI

FAAST Team Representative

EAA Flight Advisor

RV8 N18U "Sunshine"

KSBA

John Clark ATP, CFI

FAAST Team Representative

EAA Flight Advisor

RV8 N18U "Sunshine"

KSBA

GalinHdz

Well Known Member

Actually, the Van's supplied alternator is a 60A unit from a Suzuki Samari, made by Nippon Denso.

John Clark ATP, CFI

FAAST Team Representative

EAA Flight Advisor

RV8 N18U "Sunshine"

KSBA

Hmmmmmmmm I wonder if they have a 70+ amp version?

yes, they do.

Yes,

Nippon Denso makes two styles of alternators. The "small" units go from 30 amps to up to 60 amps. The "large" units go from 60 amps up to over 100 amps.

You want to use one out of a Honda. This is because auto engines rotate counterclockwise, except for Honda 4 cylinder engines [up to 2000]. Hondas and Lycomings rotate clockwise [viewed from driver's seat] Most newer Honda Accords with A/C have 70+ amp alternators.

Proper rotation ensures you will get maximum performance from the two internal fans in the large style alternator. That said, even with the fans running backwards, I doubt that you would have any issues, other than perhaps a shorter life span of the alternator.

Modern cars use serpentine belts to drive the alternator. You will need to buy a Vee belt pulley with a 15mm shaft hole to adapt a car alternator to a Lycoming. These are available at most automotive "speed" shops for a reasonable price. A 4" diameter pulley will work the best. Smaller pulleys will spin the alternator much faster than it does in a car, because the Lycoming flywheel pulley is much larger. Excessive speed will reduce the life of the rotor bearings.

The link below shows a B&C modified "small" style ND alternator.

http://www.bandc.biz/ProductImages/L40.jpg

The steel bracket and spacer tube on the alternator pivot is one of the "improvements" that B&C performs on their "small" style units. That spacer and bracket do not come on the stock ND small alternators.

The link below shows what a large ND alternator looks like

http://www.bandc.biz/alternator60ampswithbossmountbrackethomebuilt-1.aspx

Notice the much "beefier" pivot point on the large ND unit. The stock automotive ND alternators look like this. The physically larger size and the bigger pivot point are the easiest ways to differentiate a "small" from a "large" ND alternator. FYI, the rectifier diodes on the large units are much more durable. Hope this helps you.

Charlie

PS Chevy Corvair engines also rotated clockwise, but they used Delco Remy alternators, not Nippon Denso.

Hmmmmmmmm I wonder if they have a 70+ amp version?

Yes,

Nippon Denso makes two styles of alternators. The "small" units go from 30 amps to up to 60 amps. The "large" units go from 60 amps up to over 100 amps.

You want to use one out of a Honda. This is because auto engines rotate counterclockwise, except for Honda 4 cylinder engines [up to 2000]. Hondas and Lycomings rotate clockwise [viewed from driver's seat] Most newer Honda Accords with A/C have 70+ amp alternators.

Proper rotation ensures you will get maximum performance from the two internal fans in the large style alternator. That said, even with the fans running backwards, I doubt that you would have any issues, other than perhaps a shorter life span of the alternator.

Modern cars use serpentine belts to drive the alternator. You will need to buy a Vee belt pulley with a 15mm shaft hole to adapt a car alternator to a Lycoming. These are available at most automotive "speed" shops for a reasonable price. A 4" diameter pulley will work the best. Smaller pulleys will spin the alternator much faster than it does in a car, because the Lycoming flywheel pulley is much larger. Excessive speed will reduce the life of the rotor bearings.

The link below shows a B&C modified "small" style ND alternator.

http://www.bandc.biz/ProductImages/L40.jpg

The steel bracket and spacer tube on the alternator pivot is one of the "improvements" that B&C performs on their "small" style units. That spacer and bracket do not come on the stock ND small alternators.

The link below shows what a large ND alternator looks like

http://www.bandc.biz/alternator60ampswithbossmountbrackethomebuilt-1.aspx

Notice the much "beefier" pivot point on the large ND unit. The stock automotive ND alternators look like this. The physically larger size and the bigger pivot point are the easiest ways to differentiate a "small" from a "large" ND alternator. FYI, the rectifier diodes on the large units are much more durable. Hope this helps you.

Charlie

PS Chevy Corvair engines also rotated clockwise, but they used Delco Remy alternators, not Nippon Denso.

Last edited:

LifeofReiley

Well Known Member

Hmmmmmmmm I wonder if they have a 70+ amp version?

70 Amp is overkill for todays electronics... you should not need it.

Ron Lee

Well Known Member

70 Amp is overkill for todays electronics... you should not need it.

I typically run around 3 amps in flight (not counting radio transmission). Six pack instruments and one Lightspeed ignition.

GalinHdz

Well Known Member

Yes,

Nippon Denso makes two styles of alternators. The "small" units go from 30 amps to up to 60 amps. The "large" units go from 60 amps up to over 100 amps.

You want to use one out of a Honda. This is because auto engines rotate counterclockwise, except for Hondas. Hondas and Lycomings rotate clockwise [viewed from driver's seat] Most newer Honda Accords with A/C have 70+ amp alternators.

Proper rotation ensures you will get maximum performance from the two internal fans in the large style alternator. That said, even with the fans running backwards, I doubt that you would have any issues, other than perhaps a shorter life span of the alternator.

Modern cars use serpentine belts to drive the alternator. You will need to buy a Vee belt pulley with a 15mm shaft hole to adapt a car alternator to a Lycoming. These are available at most automotive "speed" shops for a reasonable price. A 4" diameter pulley will work the best. Smaller pulleys will spin the alternator much faster than it does in a car, because the Lycoming flywheel pulley is much larger. Excessive speed will reduce the life of the rotor bearings.

The link below shows a B&C modified "small" style ND alternator.

http://www.bandc.biz/ProductImages/L40.jpg

The steel bracket and spacer tube on the alternator pivot is one of the "improvements" that B&C performs on their "small" style units. That spacer and bracket do not come on the stock ND small alternators.

The link below shows what a large ND alternator looks like

http://www.bandc.biz/alternator60ampswithbossmountbrackethomebuilt-1.aspx

Notice the much "beefier" pivot point on the large ND unit. The stock automotive ND alternators look like this. The physically larger size and the bigger pivot point are the easiest ways to differentiate a "small" from a "large" ND alternator. FYI, the rectifier diodes on the large units are much more durable. Hope this helps you.

Charlie

THANKS for the info. Do these Honda alternators use an internal or external voltage regulator?

pkill

Well Known Member

Hello Galin,

Dick talks about using automobile alternators in this EAA Video…

http://www.eaavideo.org/video.aspx?v=62452525001

And while at EAA, might want to check out this EAA Alternator Webinar…

http://www.eaavideo.org/video.aspx?v=994908438001

pk

Dick talks about using automobile alternators in this EAA Video…

http://www.eaavideo.org/video.aspx?v=62452525001

And while at EAA, might want to check out this EAA Alternator Webinar…

http://www.eaavideo.org/video.aspx?v=994908438001

pk

Both

Both,

ND alternators were externally regulated up to model year 1983. The internally regulated alternators started in 1984. FYI, Chrysler switched to ND alternators over 15 years ago. They wanted to let the PCM [Powertrain Control Module aka engine computer] act as the voltage regulator in 1995. Because of this, it is possible [actually easy] to switch a late model "large" ND alternator to external regulation, using stock ND parts. Cost is about $15 for the parts. The conversion can be done without splitting the alternator cases, in less than 20 minutes.

Unless you plan on having electrically heated seats, high amp lighting or air conditioning, you won't "need" the larger style alternator. The larger style alternators will add 2.4 pounds of weight, compared to the smaller versions. What are you planning, that you feel you need the extra power?

Charlie

PS Info with photos of the mod to convert an ND internally regulated alternator to external regulation, available upon request. Send email or PM with return email info.

THANKS for the info. Do these Honda alternators use an internal or external voltage regulator?

Both,

ND alternators were externally regulated up to model year 1983. The internally regulated alternators started in 1984. FYI, Chrysler switched to ND alternators over 15 years ago. They wanted to let the PCM [Powertrain Control Module aka engine computer] act as the voltage regulator in 1995. Because of this, it is possible [actually easy] to switch a late model "large" ND alternator to external regulation, using stock ND parts. Cost is about $15 for the parts. The conversion can be done without splitting the alternator cases, in less than 20 minutes.

Unless you plan on having electrically heated seats, high amp lighting or air conditioning, you won't "need" the larger style alternator. The larger style alternators will add 2.4 pounds of weight, compared to the smaller versions. What are you planning, that you feel you need the extra power?

Charlie

PS Info with photos of the mod to convert an ND internally regulated alternator to external regulation, available upon request. Send email or PM with return email info.

Last edited:

Do you really need that extra power?

Galin,

IF you really need the extra amps, I would suggest you read the two threads linked below.

http://www.vansairforce.com/community/showthread.php?t=80290&highlight=alternator

http://www.vansairforce.com/community/showthread.php?t=49142&highlight=Nippon+Denso+alternator

Charlie

Galin,

IF you really need the extra amps, I would suggest you read the two threads linked below.

http://www.vansairforce.com/community/showthread.php?t=80290&highlight=alternator

http://www.vansairforce.com/community/showthread.php?t=49142&highlight=Nippon+Denso+alternator

Charlie

GalinHdz

Well Known Member

Both,

ND alternators were externally regulated up to model year 1983. The internally regulated alternators started in 1984. FYI, Chrysler switched to ND alternators over 15 years ago. They wanted to let the PCM [Powertrain Control Module aka engine computer] act as the voltage regulator in 1995. Because of this, it is possible [actually easy] to switch a late model "large" ND alternator to external regulation, using stock ND parts. Cost is about $15 for the parts. The conversion can be done without splitting the alternator cases, in less than 20 minutes.

Unless you plan on having electrically heated seats, high amp lighting or air conditioning, you won't "need" the larger style alternator. The larger style alternators will add two to three pounds of weight, compared to the smaller versions. What are you planning, that you feel you need the extra power?

Charlie

Because you never know what electric "gadget" will be appear in the future.

kevinh

Well Known Member

Because you never know what electric "gadget" will be appear in the future.

Though if history is a good indication - that gadget will draw less power that the gadget it replaces.

Because you never know what electric "gadget" will be appear in the future.

Galin,

With that logic, I would suggest that you install the small ND alternator. However, temporarily install a large one [a dead core unit will suffice here] temporarily, during the build. That will ensure that it won't foul your cowl. Modify the cowl, if needed for clearance, during the build. That way, you can retrofit a large ND, if and when you ever needed it in the future. Save the weight if you don't need it now.

Just a suggestion, and worth what you paid for it.

Charlie

blackbeard10

Well Known Member

honda civic 35 amp alt.

The Honda civic alternator ( 35 amp) rotates the proper way for aircraft engines The lester n. is 14184 It is a B type alternator and is externally regulated. Can be used with the B& C regulator. Autozone has them for around $ 30 with no core. Do a search on VAF with 14184

Mark Wyss

RV-4 final assembly

O 360 A1A

The Honda civic alternator ( 35 amp) rotates the proper way for aircraft engines The lester n. is 14184 It is a B type alternator and is externally regulated. Can be used with the B& C regulator. Autozone has them for around $ 30 with no core. Do a search on VAF with 14184

Mark Wyss

RV-4 final assembly

O 360 A1A

Sam Buchanan

been here awhile

The Honda civic alternator ( 35 amp) rotates the proper way for aircraft engines The lester n. is 14184 It is a B type alternator and is externally regulated. Can be used with the B& C regulator. Autozone has them for around $ 30 with no core. Do a search on VAF with 14184

Mark Wyss

RV-4 final assembly

O 360 A1A

The Honda Civic alternator also works great with a 1975 Ford LTD regulator, less than $15 at the auto parts store. This is the combo I've been running since 1999.

The Honda Civic alternator also works great with a 1975 Ford LTD regulator, less than $15 at the auto parts store. This is the combo I've been running since 1999.

Knowing how auto part prices have risen in the past four years, I thought I'd be able to call Sam out on his $15 pricing of his voltage regulator. Regular price for that voltage regulator is now $22.69 [still amazingly cheap] at Advance Auto Parts. That said, they are now on sale for $15.99! Wow. See

http://shop.advanceautoparts.com/webapp/wcs/stores/servlet/product_Voltage-Regulator-BWD_5430534-P_204_R|GRP60003_____

That voltage regulator was used on Fords for decades. They work very well and are extremely reliable on the cars they were installed on. I've only replaced a few of them [professionally] in 20 years!

Geez, I can't slip anything by Sam

Charlie

WingsOnWheels

Well Known Member

Digging up an older thread here:

I have been digging through the Auto parts websites looking for one of the small ND alternators from a honda. I have been comparing the pictures to the B&C website for reference and it looks like everything in the 55-60amp range is the large type with the full-length mounting boss. I am fine with most aspects of the larger alternator. I just really want to avoid making changes to the cowl. Has anyone mounted the large internally regulated unit? Did you have to add a bubble to the cowl? Alternatively, does anyone have a PN for the small unit (55-60amp) or year/model of fitment?

Thanks,

I have been digging through the Auto parts websites looking for one of the small ND alternators from a honda. I have been comparing the pictures to the B&C website for reference and it looks like everything in the 55-60amp range is the large type with the full-length mounting boss. I am fine with most aspects of the larger alternator. I just really want to avoid making changes to the cowl. Has anyone mounted the large internally regulated unit? Did you have to add a bubble to the cowl? Alternatively, does anyone have a PN for the small unit (55-60amp) or year/model of fitment?

Thanks,

Alternatively, does anyone have a PN for the small unit (55-60amp) or year/model of fitment?

Thanks,

Try a Lester # 14684....use it in an internet search, or on one of the common auto parts web sites - they usually cross-reference.

WingsOnWheels

Well Known Member

Try a Lester # 14684....use it in an internet search, or on one of the common auto parts web sites - they usually cross-reference.

Paul,

Thank you for the input. That number is for the SUZUKI SAMURAI alternator. Do you know if that model is designed to turn the correct direction or will the fans run backwards?

Sam Buchanan

been here awhile

Paul,

Thank you for the input. That number is for the SUZUKI SAMURAI alternator. Do you know if that model is designed to turn the correct direction or will the fans run backwards?

The direction of rotation is a moot point since it has yielded excellent field history on our planes. These alternators are lightly loaded on an RV compared to the abuse they endure on an auto.

Last edited:

WingsOnWheels

Well Known Member

After a little google time, it looks like the Samurai engine turns clockwise (facing the engine pulley). Assuming the alternator is mounted the same direction that would indicate that use on a Lycomming would be reverse direction (CCW looking at the fron of the pulley).

Has anoyone found a small ND alternator fit from a Honda?

Has anoyone found a small ND alternator fit from a Honda?

Last edited:

I posted this a couple of months ago about my experience with car alternators. Search the archives, there are many posts on this subject. Dan

Alternator replacement -9A O-360-A4M

Guys: Last Saturday, 20 minutes after departure, my alternator quit, 0 amps and 11.9 volts and dropping. Returning to Reno-Stead I removed the confirmed failed unit (900 hours-5 years, aviation isle of Kragen Auto Parts ) and proceded to the aviation isle of O'Riellys. I was able to duplicate the alternator as a 1986 Suzuki Samurai 14870 made by Ultima. It fit perfectly and the included pulley lined up with the Lycoming starter ring. It is a refurbished lifetime 70A unit for $88 plus change. Now before you start, I know what it is and where it came from and what to expect. The original Van's unit lasted 26 hours, the second as mentioned above, 900+ hours, and the fan rotated the wrong way, but it had a blast tube on the diode pack. I figure my time is free, and I can replace several of the lifetime warranty "auto quality" units for less than 1/3 the cost of one "approved good" units without a lifetime warranty. I'm also the guy who uses car gas (91 RON) with ethanol, what else could you expect from a guy like me? Dan

Alternator replacement -9A O-360-A4M

Guys: Last Saturday, 20 minutes after departure, my alternator quit, 0 amps and 11.9 volts and dropping. Returning to Reno-Stead I removed the confirmed failed unit (900 hours-5 years, aviation isle of Kragen Auto Parts ) and proceded to the aviation isle of O'Riellys. I was able to duplicate the alternator as a 1986 Suzuki Samurai 14870 made by Ultima. It fit perfectly and the included pulley lined up with the Lycoming starter ring. It is a refurbished lifetime 70A unit for $88 plus change. Now before you start, I know what it is and where it came from and what to expect. The original Van's unit lasted 26 hours, the second as mentioned above, 900+ hours, and the fan rotated the wrong way, but it had a blast tube on the diode pack. I figure my time is free, and I can replace several of the lifetime warranty "auto quality" units for less than 1/3 the cost of one "approved good" units without a lifetime warranty. I'm also the guy who uses car gas (91 RON) with ethanol, what else could you expect from a guy like me? Dan

hgerhardt

Well Known Member

Digging up an older thread here:

I have been digging through the Auto parts websites looking for one of the small ND alternators from a honda. I have been comparing the pictures to the B&C website for reference and it looks like everything in the 55-60amp range is the large type with the full-length mounting boss. I am fine with most aspects of the larger alternator. I just really want to avoid making changes to the cowl. Has anyone mounted the large internally regulated unit? Did you have to add a bubble to the cowl? Alternatively, does anyone have a PN for the small unit (55-60amp) or year/model of fitment?

Thanks,

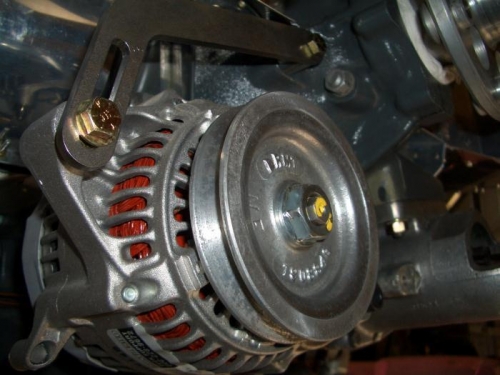

Actually, there are more than "small" and "large" Denso alternators. What you're thinking of is a medium size, pictured below. An '86 Honda Civic unit (60A) is what I have in my -6 and fits the cowl just fine. Only mod you need to do is replace the multi-rib pulley with a V-belt pulley. Granted, that can be difficult if you're in BFE when it dies, but 5 min to swap with an impact wrench. Lester 14759 is the interchange p/n. This unit, as all pre-2000 Honda 4-cylinders, is CCW rotation (same as a Lyc, so the cooling fan is correct).

If you're interested, search my username on this site and find the article I wrote on how to mod Denso alternators so that you have complete shutdown control (not unlike how one of our favorite vendors does it).

Here's a pic of the Civic unit:

WingsOnWheels

Well Known Member

Thank you! This is exactly what I needed to hear. FYI: I was in the business for a number of years and most auto parts retailers (even the chain ones) will swap the pully for you or give you the tools to do it. I did this many time on customer units since the rebuild often does not include a pulley.

Actually, there are more than "small" and "large" Denso alternators. What you're thinking of is a medium size, pictured below. An '86 Honda Civic unit (60A) is what I have in my -6 and fits the cowl just fine. Only mod you need to do is replace the multi-rib pulley with a V-belt pulley. Granted, that can be difficult if you're in BFE when it dies, but 5 min to swap with an impact wrench. Lester 14759 is the interchange p/n. This unit, as all pre-2000 Honda 4-cylinders, is CCW rotation (same as a Lyc, so the cooling fan is correct).

If you're interested, search my username on this site and find the article I wrote on how to mod Denso alternators so that you have complete shutdown control (not unlike how one of our favorite vendors does it).

Here's a pic of the Civic unit:

NickAir

Well Known Member

Plane Power

I had the auto type alternator. As others, my alternator's mounting ear cracked. I upgraded to what Van's offers now, PlanePower alternators.

They are manufacturers of both certified and experimental alternators.

I like PlanePower alt much better. Other say it will last longer than the engine. My original auto alternator only lasted 300 hours. Not impressed with it since I talked to others that had same story. I say go with Plane power alternator that Van's now offers, it even comes with a belt and easy install.

Just my experience.

I had the auto type alternator. As others, my alternator's mounting ear cracked. I upgraded to what Van's offers now, PlanePower alternators.

They are manufacturers of both certified and experimental alternators.

I like PlanePower alt much better. Other say it will last longer than the engine. My original auto alternator only lasted 300 hours. Not impressed with it since I talked to others that had same story. I say go with Plane power alternator that Van's now offers, it even comes with a belt and easy install.

Just my experience.

Sam Buchanan

been here awhile

I had the auto type alternator. As others, my alternator's mounting ear cracked. I upgraded to what Van's offers now, PlanePower alternators.

They are manufacturers of both certified and experimental alternators.

I like PlanePower alt much better. Other say it will last longer than the engine. My original auto alternator only lasted 300 hours. Not impressed with it since I talked to others that had same story. I say go with Plane power alternator that Van's now offers, it even comes with a belt and easy install.

Just my experience.

If there is a problem with a mounting ear cracking I would have to suspect the mounting brackets have a slight mis-alignment. Case cracking isn't a problem with automotive installations. The Plane Power is a good alternator (but there have been failures with them as well) but case cracking shouldn't occur with any alternator.

db1yg

Well Known Member

I have been using a ND 55 amp from a 1987 Suzuki Samari on my IO360/9a for 400+ hrs with never a hick up. It is a rebuilt model (Boosch rebuild) with a life time warranty purchased from the aviation section of NAPA auto parts.

In normal daytime cruise, with everything on--a/p, radios, strobes, etc. the amp draw does not exceed 16 amps---it is plenty of power for the RV.

Cheers,

db

In normal daytime cruise, with everything on--a/p, radios, strobes, etc. the amp draw does not exceed 16 amps---it is plenty of power for the RV.

Cheers,

db

WingsOnWheels

Well Known Member

I have been thinking it over and would like to stick with an externally regulated alternator so I have better control over the field lead. While there are modifications that allow that control or to convert an internal to external, it takes away the big advantage of the auto alternator. That advantage is the ability to walk into an autoparts store almost anywhere in the counrty and come out with a new alternator. If mods have to be made that is not accomplished as readily.

On that note, has anyone found a 55-60+ amp externally regulated alternator, preferably CCW rotation (facing the pully), with internal fans, that is a size similar to the Honda or Suzuki units?

On that note, has anyone found a 55-60+ amp externally regulated alternator, preferably CCW rotation (facing the pully), with internal fans, that is a size similar to the Honda or Suzuki units?

rocketbob

Well Known Member

Check out the B&C, made for airplanes and works great. Personally I can't understand why so many people will spend megabucks on avionics equipment and then use the cheapest alternator they can find to power them

The -6 I fly has a B&C in it, and its been acting flaky lately. Dropping out for a few seconds then coming back online. Nothing wrong with the wiring. I'll take anything that can be locally sourced any day over some overhyped aviation equivalent.

Because these alternators provide a better cost/risk value than the "high-quality" alternators.Check out the B&C, made for airplanes and works great. Personally I can't understand why so many people will spend megabucks on avionics equipment and then use the cheapest alternator they can find to power them

I know of two instances where a high-dollar alternator has a failed within 1-2 years. Broken wires and loose connections have bitten me, but my cheap Nippon alternators have never left me stranded in 12.5 years and 1550 hrs.

Many of us know that spending $130 for a 55 amp alt every 3-4 years (if replaced proactively as I do) as opposed to spending $600 upfront for a 8-10 yr life is simply better time-value use of limited funding.

And I know if I'm on a trip and something does happen, I can catch a ride down to the local AutoZone and buy a new one in almost any mid-size city in the country.

Last edited:

Sam Buchanan

been here awhile

Check out the B&C, made for airplanes and works great. Personally I can't understand why so many people will spend megabucks on avionics equipment and then use the cheapest alternator they can find to power them

The only thing I ask of my alternator is to charge the battery.......

Paul,

Thank you for the input. That number is for the SUZUKI SAMURAI alternator. Do you know if that model is designed to turn the correct direction or will the fans run backwards?

Colin,

I haven't viewed this thread in a long time. I'm not sure if anyone has answered your question. the 14684 alternator that Paul mentioned [85 to 89 Chevy Geo and Suzuki Samari] does rotate clockwise, like a Lycoming. It turns in the correct direction. See

http://www.obbstartersandalternators.com/denso-14684n-p-1143.html

It also has a pivot mount, which supports both the front and rear of the alternator, compared to most of the smaller internally regulated ND alternators. Most small IR models only have pivot mounting points at the front. The older, 14131 externally regulated ND alternators also have front and rear pivot supports.

I am going to "borrow" one of these from my auto parts vendor. I want to see if the external regulator conversion parts [used on the 70 to 120 amp models] will work on this unit. I'll report again, once I know.

Charlie

Last edited:

Lester # 14870 is another option

The Lester 14870 is an internally regulated, 55 amp, clockwise rotation alternator with a Vee belt pulley. It will also work. It was used on:

1987-88 Chevy Sprint

1985-88 Pontiac Firefly

1985-89 Suzuki Samurai

1992-93 Suzuki Samurai JA

1989 Suzuki Sidekick

1985-88 Suzuki Forsa

These are not real popular cars, but if you need a replacement and the store is out of the 14684, you could probably use it. Mounting my be different?

Charlie

The Lester 14870 is an internally regulated, 55 amp, clockwise rotation alternator with a Vee belt pulley. It will also work. It was used on:

1987-88 Chevy Sprint

1985-88 Pontiac Firefly

1985-89 Suzuki Samurai

1992-93 Suzuki Samurai JA

1989 Suzuki Sidekick

1985-88 Suzuki Forsa

These are not real popular cars, but if you need a replacement and the store is out of the 14684, you could probably use it. Mounting my be different?

Charlie

albertaflyer

Active Member

FYI... A friend of mine bought an RV6A from a gentlemen. He was back from a local flight only to find holes in his cowling. After taking the cowling off he found the culprit. The fan in the alternator blew up. It was a Wilson alternator. He phoned the manufacturer and come to find out that with the pulley setup he had that the alternator was turning at roughly 9000 RPM at cruise. The alternator was designed to turn a max. of 4500 RPM. He went to an aircraft specific alternator!

BSwayze

Well Known Member

FYI... A friend of mine bought an RV6A from a gentlemen. He was back from a local flight only to find holes in his cowling. After taking the cowling off he found the culprit. The fan in the alternator blew up. It was a Wilson alternator. He phoned the manufacturer and come to find out that with the pulley setup he had that the alternator was turning at roughly 9000 RPM at cruise. The alternator was designed to turn a max. of 4500 RPM. He went to an aircraft specific alternator!

Hmmmm.... it's kinda hard to blame this on the alternator, isn't it? I can't help but wonder how long his aircraft specific alternator would last if it turned at 9,000 rpm. ???

WingsOnWheels

Well Known Member

Hmmmm.... it's kinda hard to blame this on the alternator, isn't it? I can't help but wonder how long his aircraft specific alternator would last if it turned at 9,000 rpm. ???

From the information I have found from some of the aftermarket alternator suppliers (powermaster) and other net searches, most newer automotive alternators can run upto 16,000 RPM for short durations. Makes sense for cars with small displacement engines that run at high rpm for short periods of time.

Not directly related to the quote above, but good information for those looking for an automotive alternator:

When discussing the direction of rotation the alternator manufacturs speak in terms facing the pulley, while aircraft engines are from the pilot seat (in a tractor config). So the lycomming turns clockwise but a clockwise alternator is actually intended for the opposite direction. Facing the prop from the front of the aircraft and facing the alternator pulley you need an alternator that turns counterclockwise. Alternators can run either direction, so the only impact is on the cooling fans. The 'ideal' auto alternator would be listed as CCW rotation.

I have found an alternator that looks like it will work well. It is a denso-type call it medium size (118mm stator). It fits using the universal bracket from ACS and has good clearance to the cowl.

The alternator is externally regulated (my #1 goal) with dual internal fans (running the wrong direction of course). The output is well more than we need (90amps). The only issues are the pulley since it comes with a serpentine not V pulley. I have a possible fix for the pulley, but am still looking for a better solution that will better work with our engine speed and drive pulley size. The size of the alternator does limit the belt adjustment travel so belt choice is critial to allow adjustment for strech. At cruise power the alternator should spin at least 6K+ RPM and with my current pulley I am closer to 5K.

Last edited:

WingsOnWheels

Well Known Member

Colin, will you please share the model number of the alternator you're exploring?

Sorry, I should have included that information:

Autozone P/N: 13208, 13208VC

Napa P/N: RAY 2138624, RAY 2138613

The different P/Ns are cost-level (basic vs premium, ect). Autozone has the best price so far.

Fitment 1998 Dodge Dakota and many others. This appears to be a widly used part and is a regular stocking items at most locations.

I am still not 100% decided on this part until I figure out a proper pulley. For now I modified the pulley from the old generator to work, the it is too large to spin the alternator at the proper speed.

Edit: One thing to note, this alternator has an isolated field (two field terminals) so you can use either a ford, GM, Dodge, or aviation regulator. For the Ford or Most aviation regulators, just take one field pole to ground and the other to the regulator.

Edit2: Mounting holes at the attach bracket are 10mm, I used shoulder bolts and drilled them for castle nuts. The adjuster arm hole is some loose ~13mm size. I made a spacer to size that down to 5/16.

There is more clearance than would appear, around 3/4"+. As a plus, the case will hit the cowl before the pulley, so you don't have a sawblade grinding away in the event they touch. The up travel is limited by the back of the alternator hitting the cly base flange.

Last edited: