Brantel

Well Known Member

I received most of one of Marvin's kits (Smoke System Helper) for Christmas and promptly ordered the rest of the parts that Santa did not bring me. Marvin was a joy to work with and sent my remaining parts right away.

I even ordered a drum of smoke oil from him and was sorta shocked at the delivery price. Compared to purchasing 5 gallons at a time, the drum is the only way to go! I should have enough oil to last me a long time! The oil was delivered very fast!

His kit is very complete. He bags everything up in zip lock bags and includes directions in all the little sub-kits. There will be parts left over because he includes enough stuff to allow for flexibility in how you mount everything as well as for the different airplane types.

I did find that the longer bolts included for the seat belt attach point tank mounts were too long and I had to find some shorter ones. I also found that the screws included to mount the top of the tank to the tip-up seat back brace were almost too short. Nothing major, just trying to be accurate in my review.

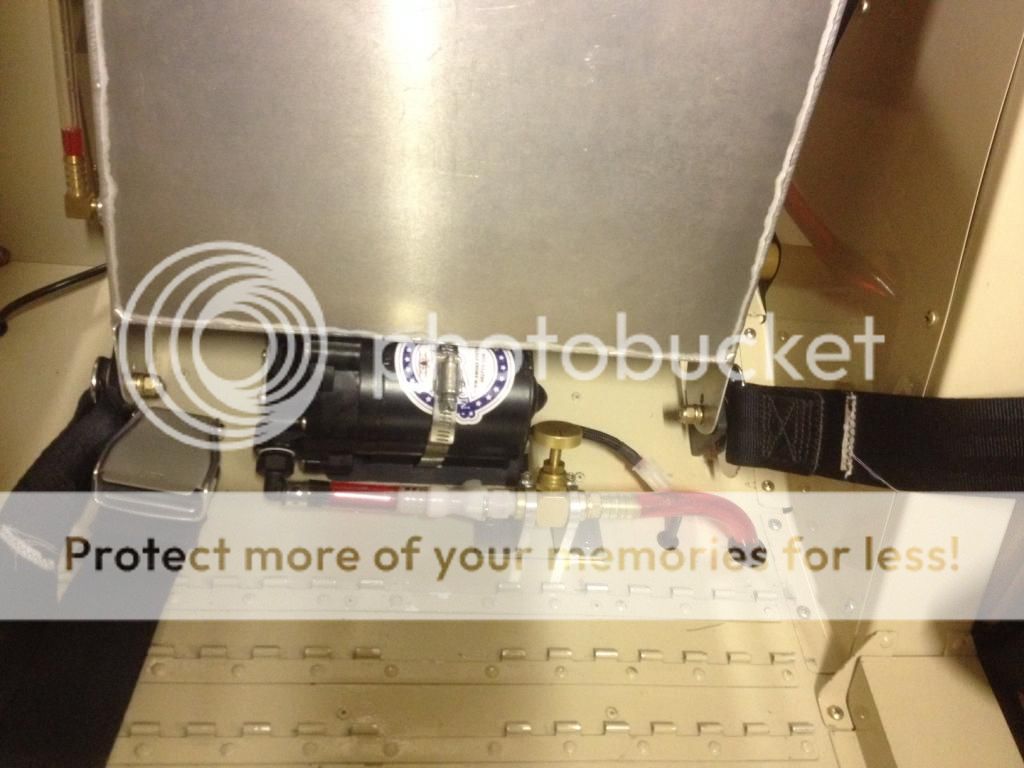

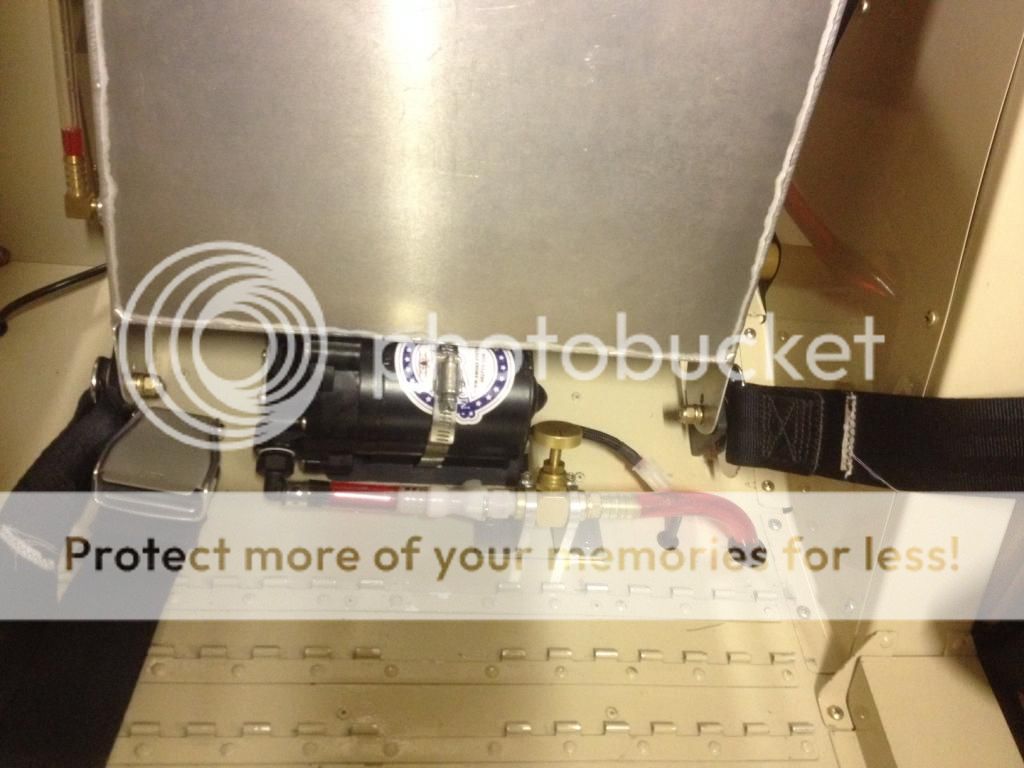

The "hidden" tank is a work of art and fits really nice behind the seat. It truly does sort of disappear back there. I decided to mount the pump in front of the tank to the floor pan with a hose clamp. It fits nicely in that area between the tank and the back of the seat. I removed the base from the pump and used the hose clamp running thru a couple slots in the floor pan to hold it in place. Some baffle material to cushion it. It hides the pump from view since it is between the seat and the tank! I got the idea from JohnFurey's post and picture:

PICTURE CREDIT TO JohnFurey...this is his install not mine... I shamelessly copied some of it.

I decided to run the oil line thru the spar. To accomplish this without making a massive hole for the included rubber hose, I decided to transition from rubber to aluminum and then back to rubber after passing thru the spar. This makes the hole required only 1/2". Due to the geometry involved I decided to make the double transition to rubber. I just ordered those parts from ACS ahead of time. Put the hole in the spar by following the new recommendations as written by Van's for adding holes to the spar. Here is a pic of the transition. The other end looks the same just opposite....

Somehow I managed to miff up one of the Aeroquip hose end fittings and stripped it out. I think I either had a stainless braid strand get in there or I over torqued it. Just be careful with these. It was totally my fault that I stripped this out...

Even though it was sub 20° today and we got 7.5" of snow, I went to the hangar (heated with a portable propane heater ) and finished up my install today. Checked everything out, checked for leaks, flow tested and tweaked the restrictor valve trying to get 0.5 gpm but could only get .33 or so and finally tested it with the engine running:

) and finished up my install today. Checked everything out, checked for leaks, flow tested and tweaked the restrictor valve trying to get 0.5 gpm but could only get .33 or so and finally tested it with the engine running:

I flew it later but there was no one around to tell me how it was performing. No video of it in the air .

.

I even ordered a drum of smoke oil from him and was sorta shocked at the delivery price. Compared to purchasing 5 gallons at a time, the drum is the only way to go! I should have enough oil to last me a long time! The oil was delivered very fast!

His kit is very complete. He bags everything up in zip lock bags and includes directions in all the little sub-kits. There will be parts left over because he includes enough stuff to allow for flexibility in how you mount everything as well as for the different airplane types.

I did find that the longer bolts included for the seat belt attach point tank mounts were too long and I had to find some shorter ones. I also found that the screws included to mount the top of the tank to the tip-up seat back brace were almost too short. Nothing major, just trying to be accurate in my review.

The "hidden" tank is a work of art and fits really nice behind the seat. It truly does sort of disappear back there. I decided to mount the pump in front of the tank to the floor pan with a hose clamp. It fits nicely in that area between the tank and the back of the seat. I removed the base from the pump and used the hose clamp running thru a couple slots in the floor pan to hold it in place. Some baffle material to cushion it. It hides the pump from view since it is between the seat and the tank! I got the idea from JohnFurey's post and picture:

PICTURE CREDIT TO JohnFurey...this is his install not mine... I shamelessly copied some of it.

I decided to run the oil line thru the spar. To accomplish this without making a massive hole for the included rubber hose, I decided to transition from rubber to aluminum and then back to rubber after passing thru the spar. This makes the hole required only 1/2". Due to the geometry involved I decided to make the double transition to rubber. I just ordered those parts from ACS ahead of time. Put the hole in the spar by following the new recommendations as written by Van's for adding holes to the spar. Here is a pic of the transition. The other end looks the same just opposite....

Somehow I managed to miff up one of the Aeroquip hose end fittings and stripped it out. I think I either had a stainless braid strand get in there or I over torqued it. Just be careful with these. It was totally my fault that I stripped this out...

Even though it was sub 20° today and we got 7.5" of snow, I went to the hangar (heated with a portable propane heater

I flew it later but there was no one around to tell me how it was performing. No video of it in the air

Last edited: