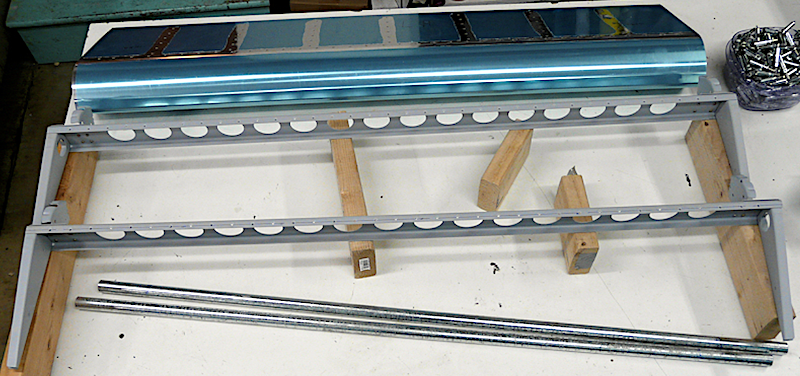

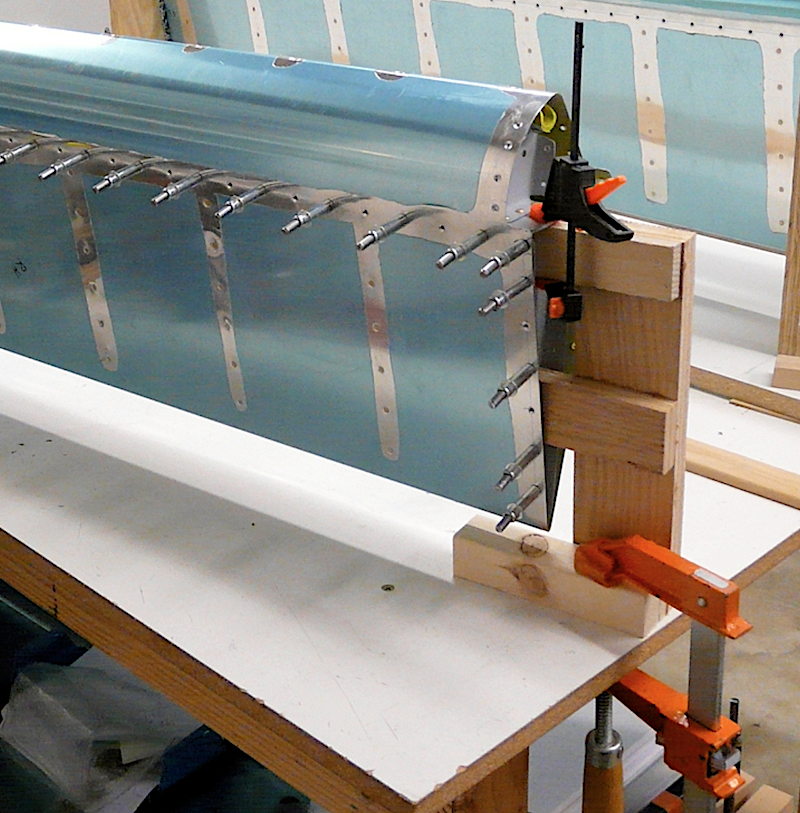

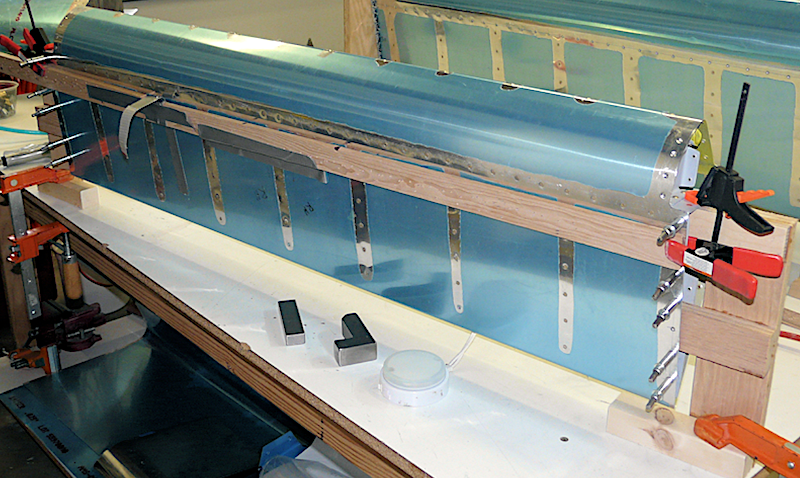

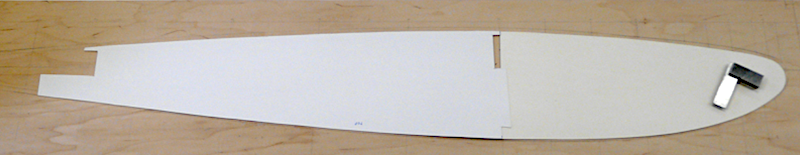

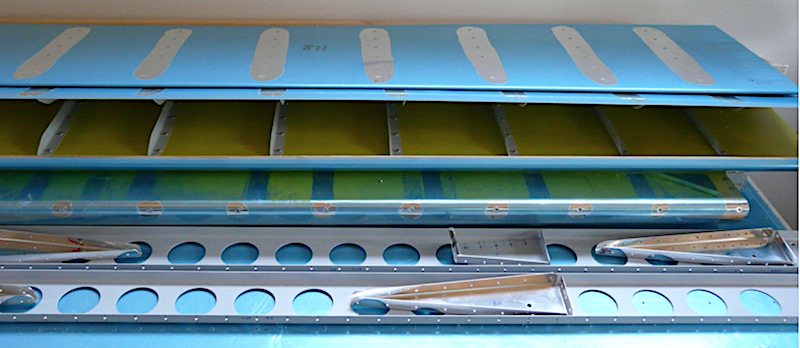

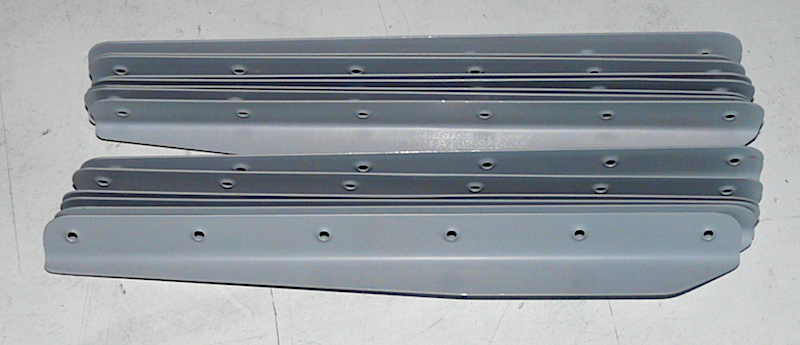

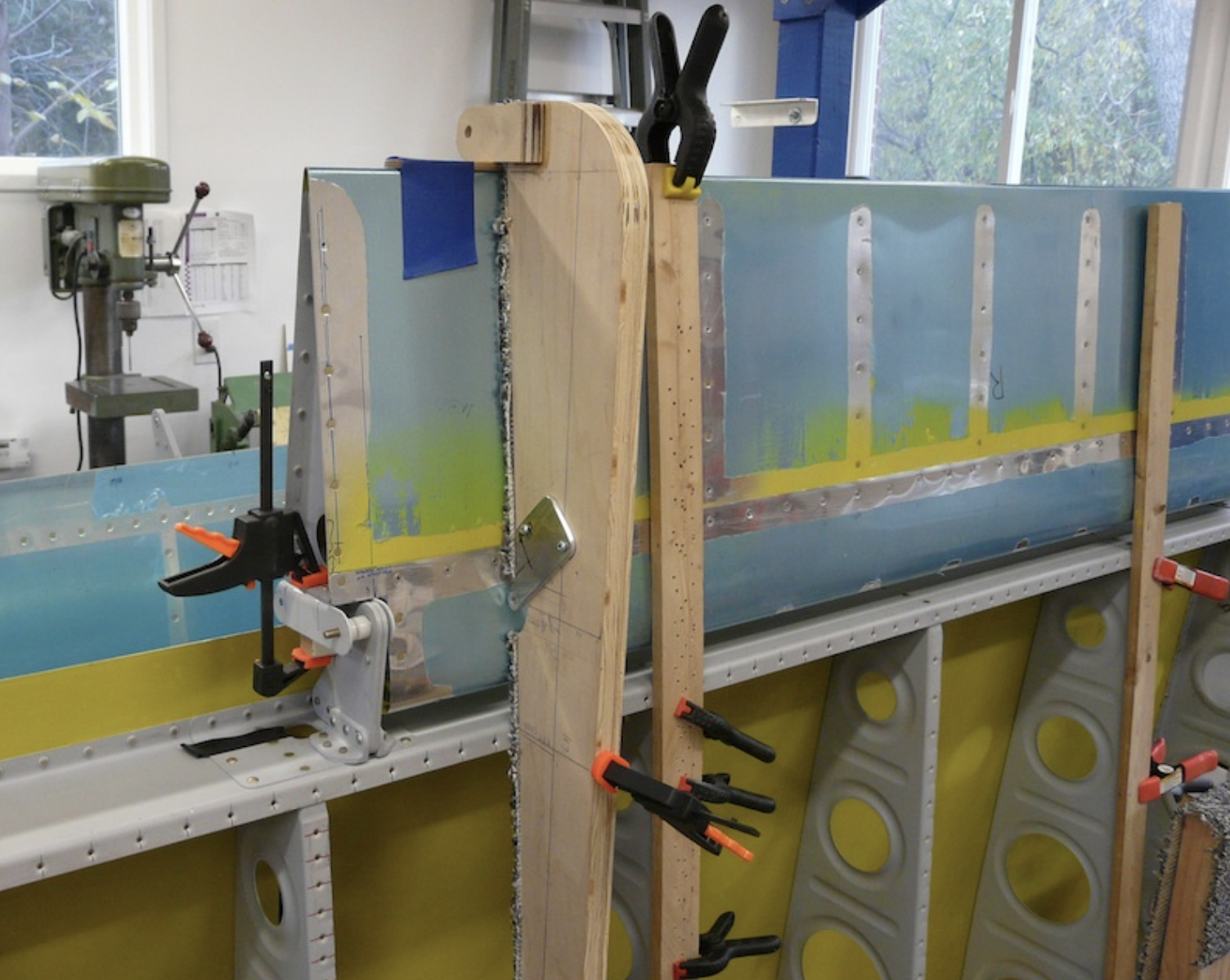

The third left aileron continues. When those lightening holes are drilled, the spar warps just a bit. The clecos in the previously-drilled holes through the spar flange and the skin hold that flange nicely in position, and I clamped a straight piece of steel angle to the spar web to hold the bottom flange relatively straight. Then I drilled the holes though the bottom skin and the spar flange.

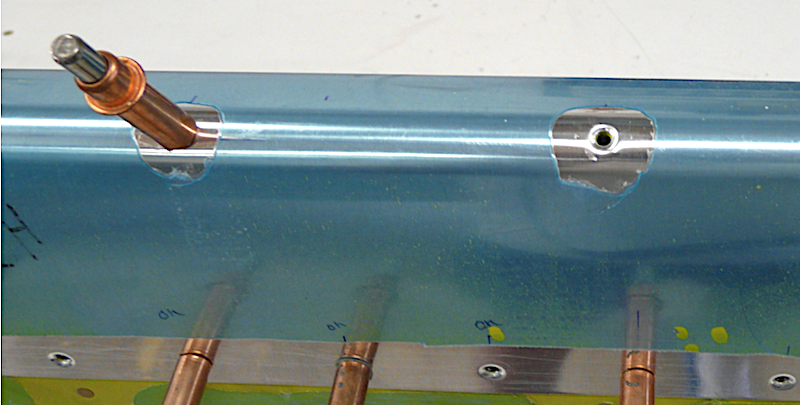

The leading edge needed a bit more bending around the pipe. To do that, I wanted something a bit smaller diameter than the pipe, so I used the stock for the aileron pushrods. I taped it to the skin and massaged the bend and this worked nicely. Ideally, I should have done this before drilling the bottom flange holes but it turned out okay. It did leave a small gap which the rivets pulled down nicely.

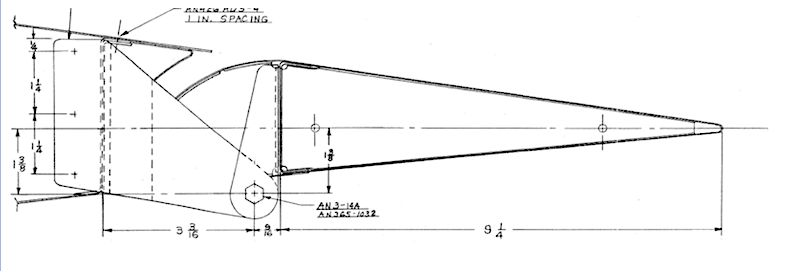

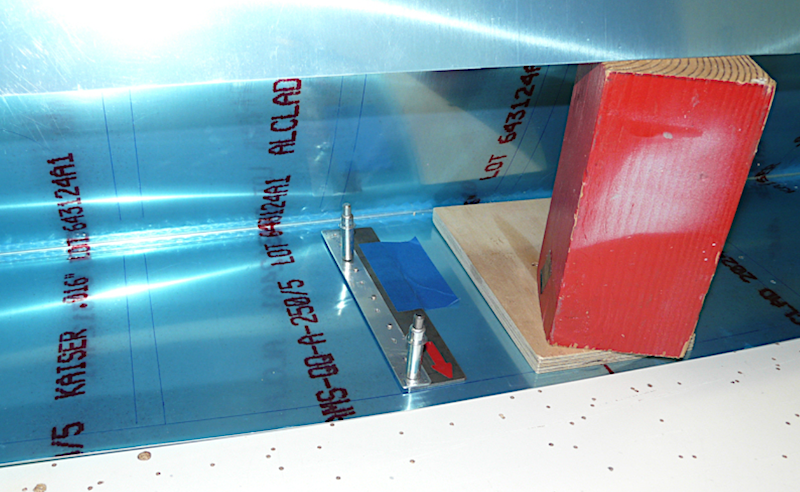

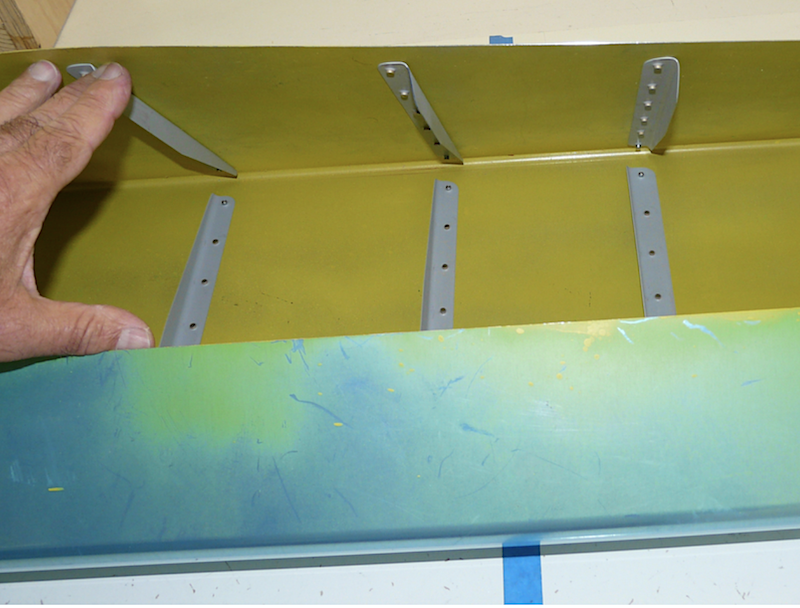

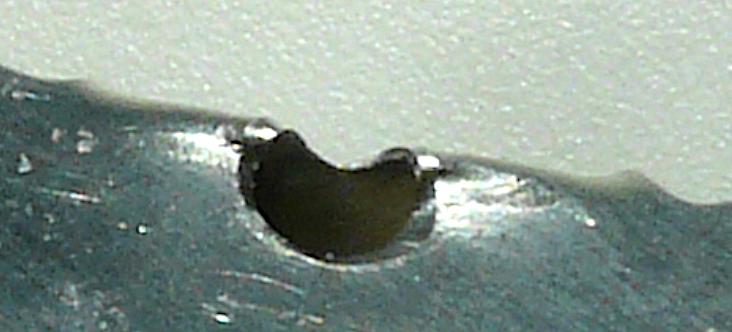

Shortly it was time to rivet the top flange of the spar to the skin. I'd previously done this by riveting with the gun's set supported by a wooden batten and using an "L"shaped bucking bar to get in to the shop side of the rivets as shown in post #157. The constraints can be seen here.

https://i.imgur.com/SHb7FeP.pngIMG]

Look for the skin overlap on the right; that what I needed to work though, with that overlap opened up and riveting the flange on the left. I was able to do one aileron successfully that way all by myself. I ruined one more by myself and one additional one with the help of a friend - that .016 skin is very fragile.

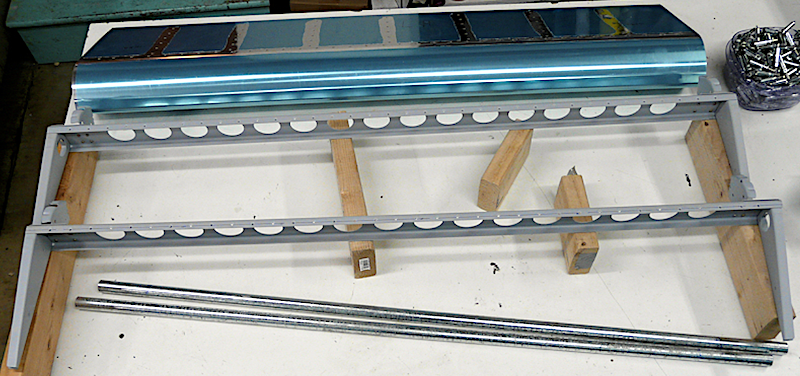

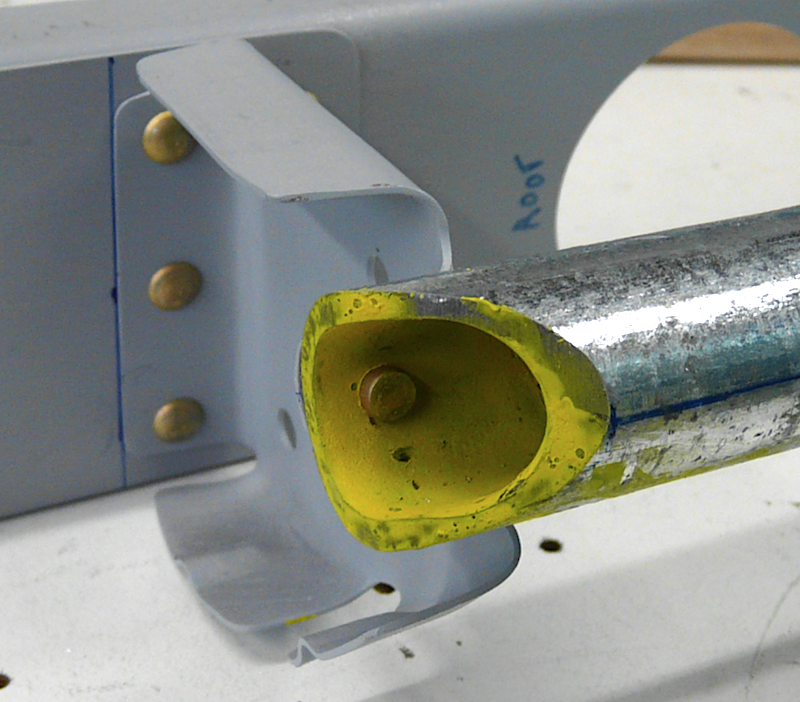

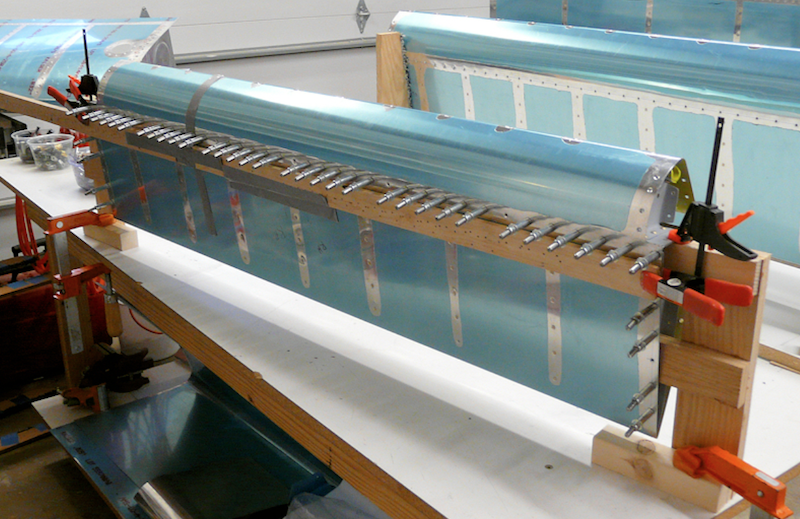

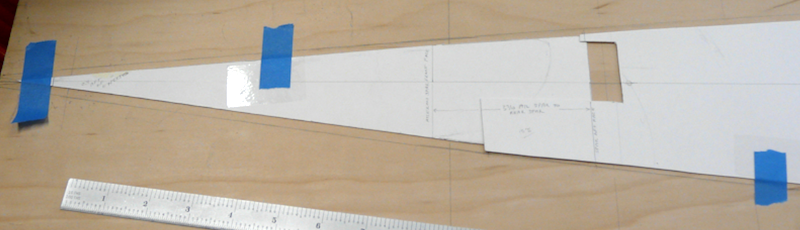

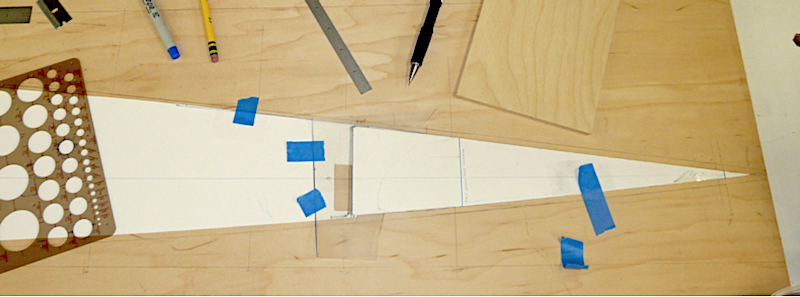

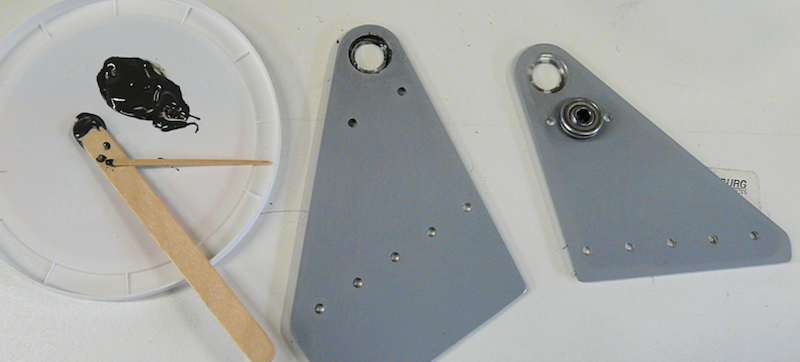

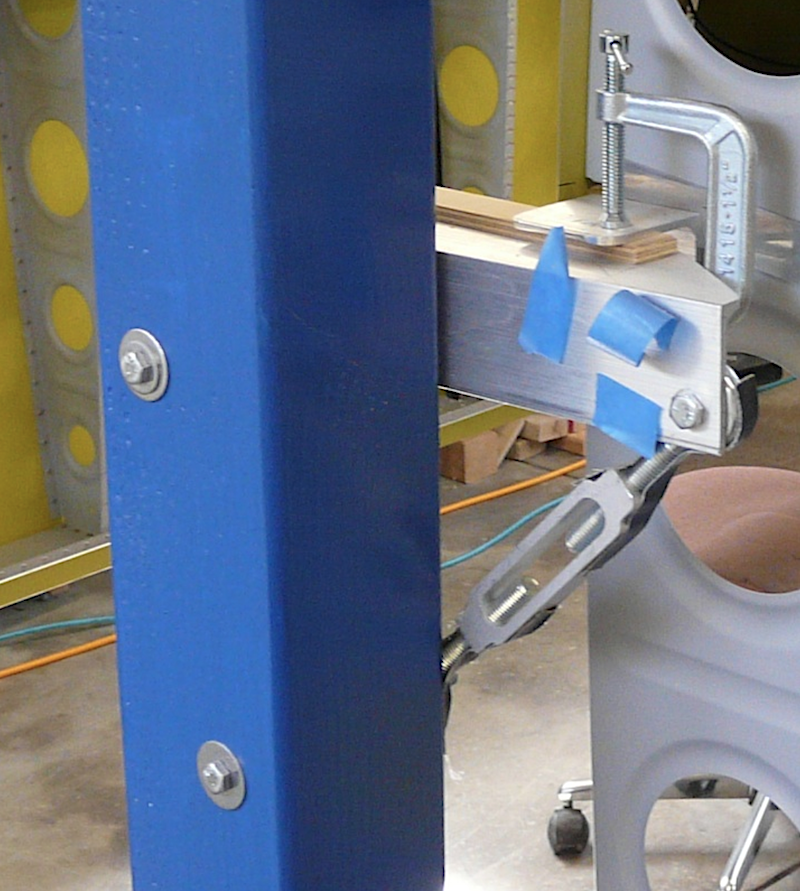

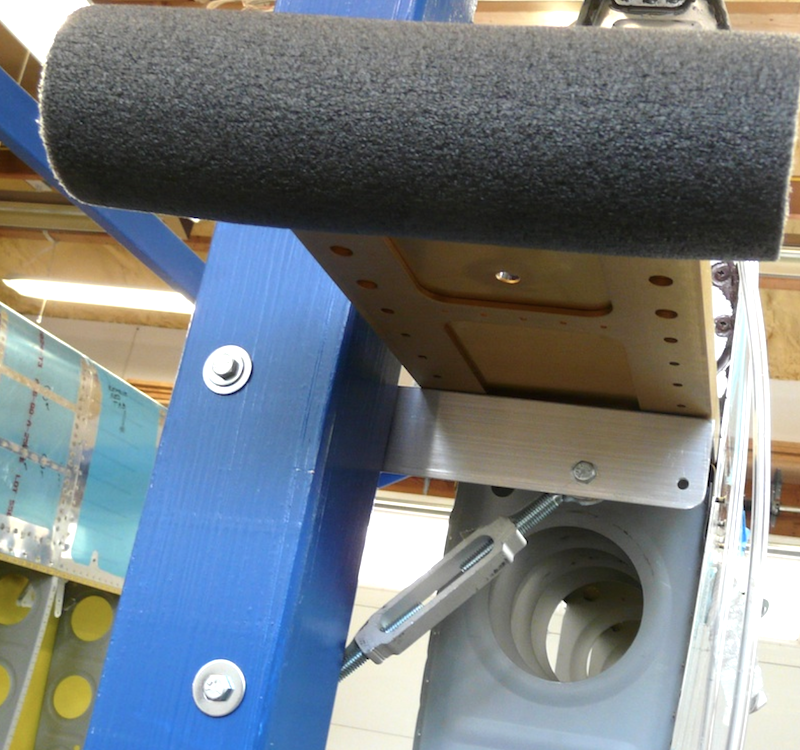

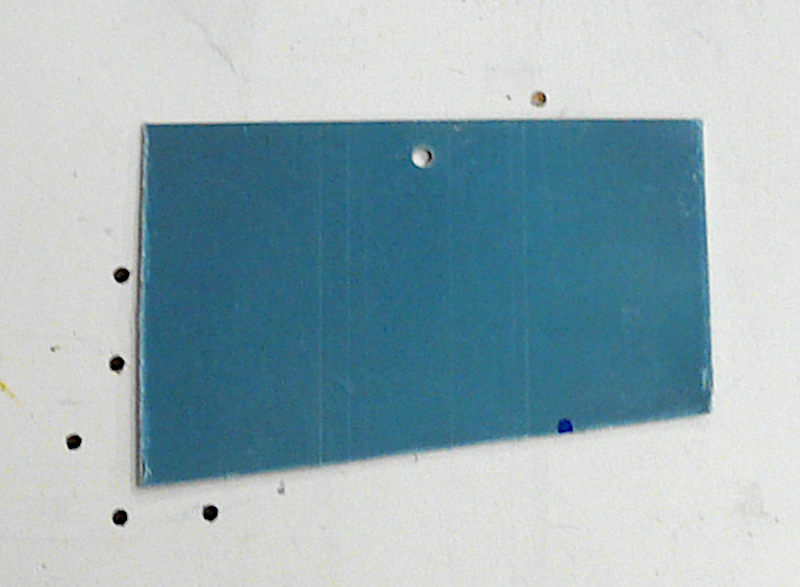

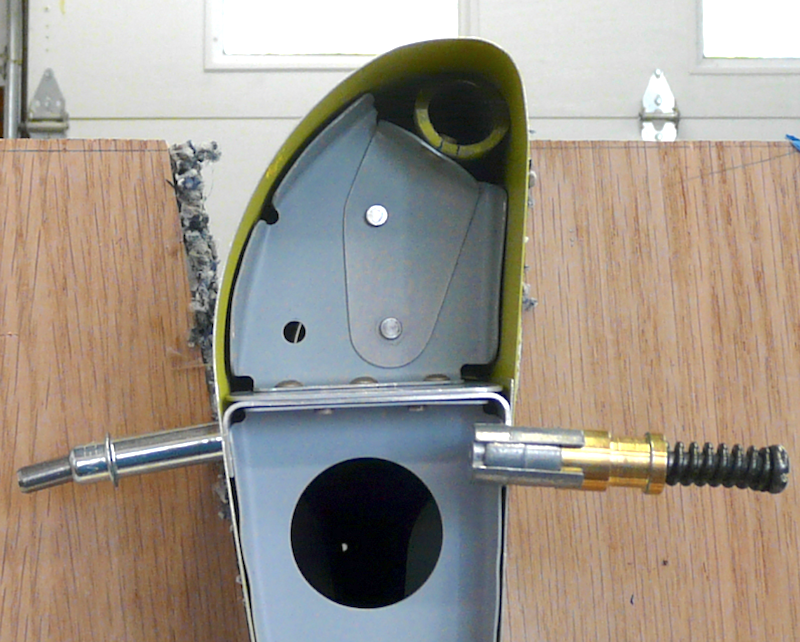

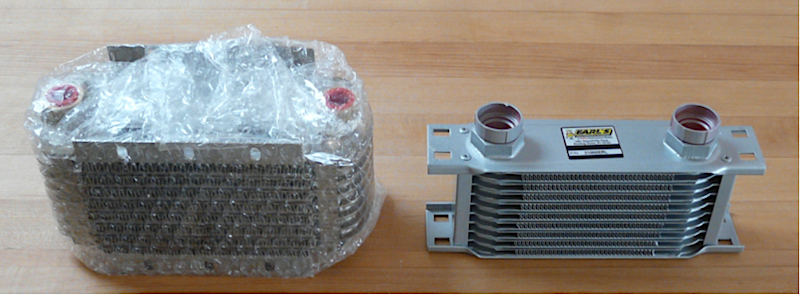

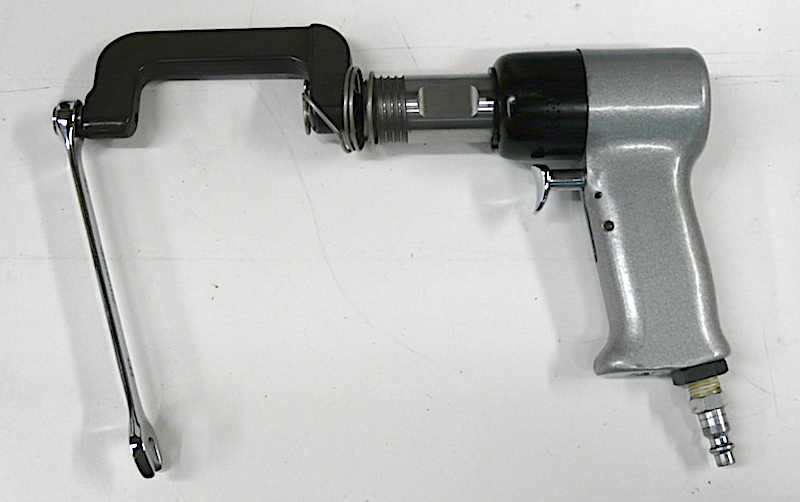

This time I decided to see if perhaps I could back-rivet it. As you might predict, the straight back riveting set wouldn't get to the flange. I didn't find an offset back riveting tool so I started looking for something, anything, that might do the job. What I found was a "C" tool. This nifty device is driven directly by the rivet gun as shown, and has a 3/16" hole in the other end for any rivet or dimpling set you might wish.

[IMG]https://i.imgur.com/sb5A1Pu.png

Look for the skin overlap on the right; that what I needed to work though, with that overlap opened up and riveting the flange on the left. I was able to do one aileron successfully that way all by myself. I ruined one more by myself and one additional one with the help of a friend - that .016 skin is very fragile.

This time I decided to see if perhaps I could back-rivet it. As you might predict, the straight back riveting set wouldn't get to the flange. I didn't find an offset back riveting tool so I started looking for something, anything, that might do the job. What I found was a "C" tool. This nifty device is driven directly by the rivet gun as shown, and has a 3/16" hole in the other end for any rivet or dimpling set you might wish.

I bought this one from The Yard Store.

For what it's worth, the rivet set at the left end is 1/2" long and 1/2" diameter. The box-end wrench is a cheap HF one, 1/2" size.

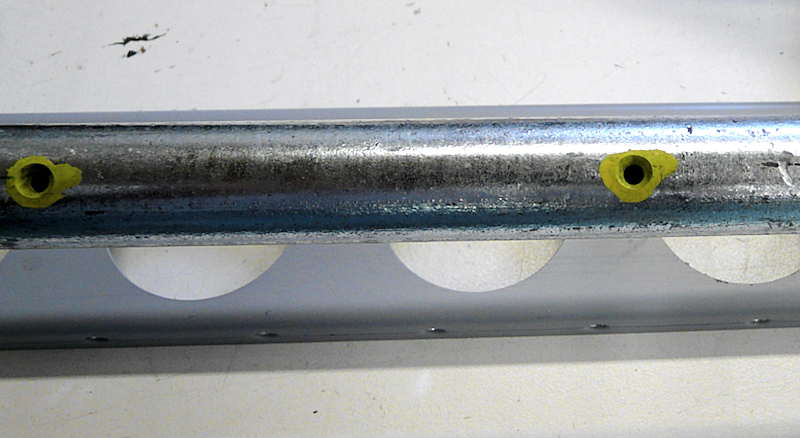

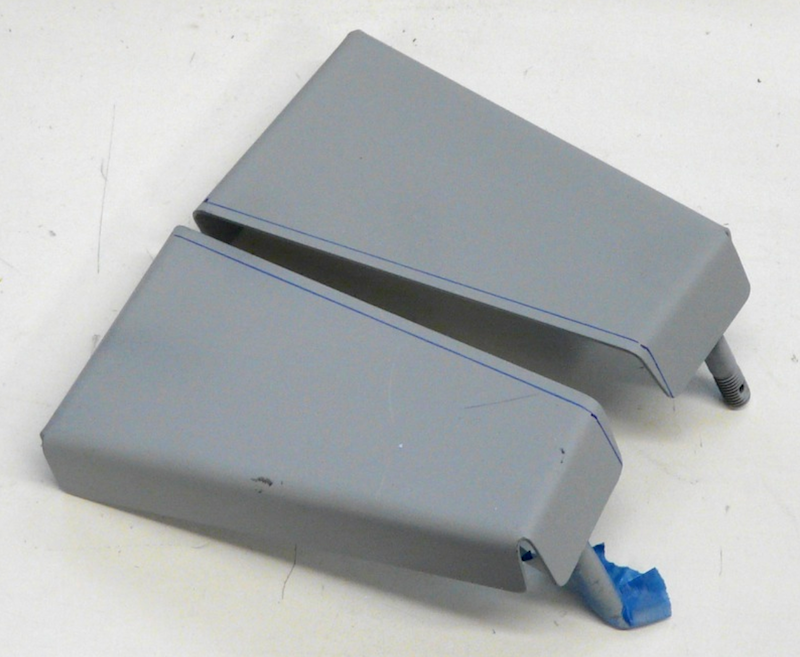

It still took some care, since the access was awkward and it took two hands: one on the gun and the other pressing the spar flange to the skin with the box-end wrench. The box-end wrench substituted for the plastic spring-loaded tube usually found on back-rivet sets.

I quickly found that the 2x gun, pictured, which I usually use for the 3/32" rivets, was not powerful enough to drive these rivets. I had to use a 3x gun and crank the air pressure up to about 43 or 44 psi. Then it worked okay. That gave me a nice smoothly-driven row of rivets.

Success.

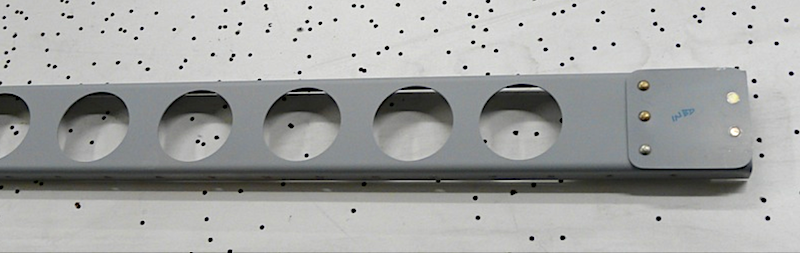

Worth mentioning but not pictured, sorry, is that on this aileron I used shims between the spar web and the nose rivet back flange. Both sides use .120" thick shims, and the need for shims on the upper or lower flanges was much reduced.

Dave