boom3

Well Known Member

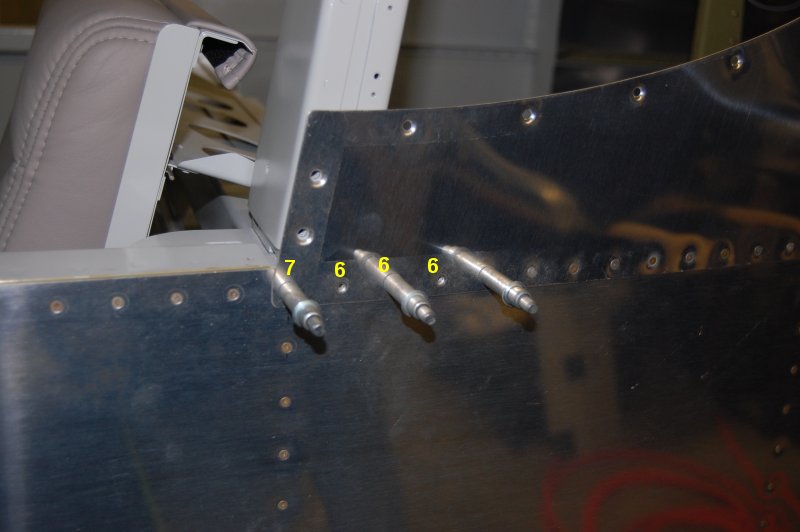

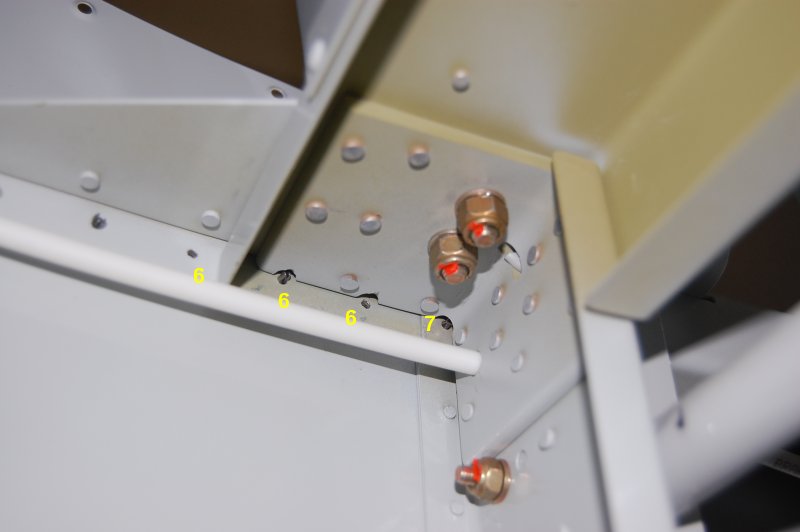

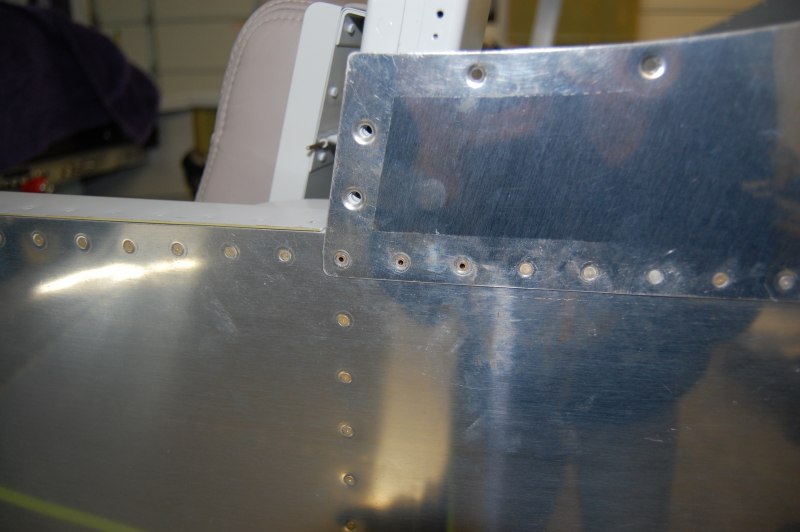

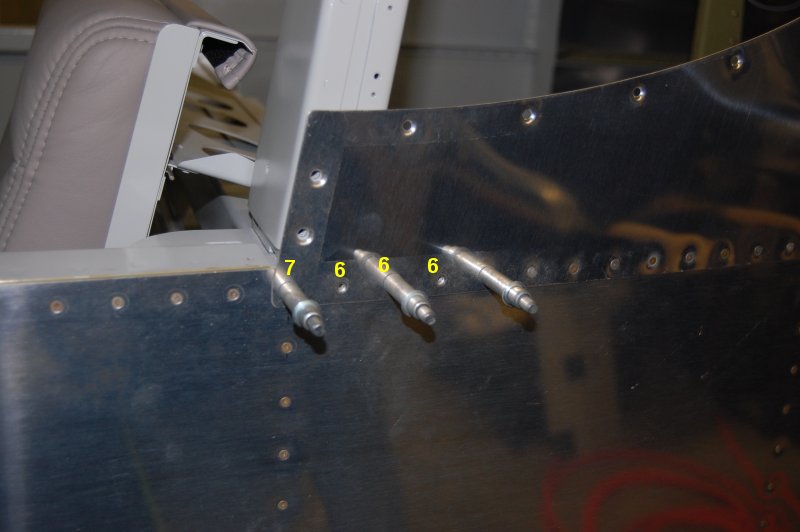

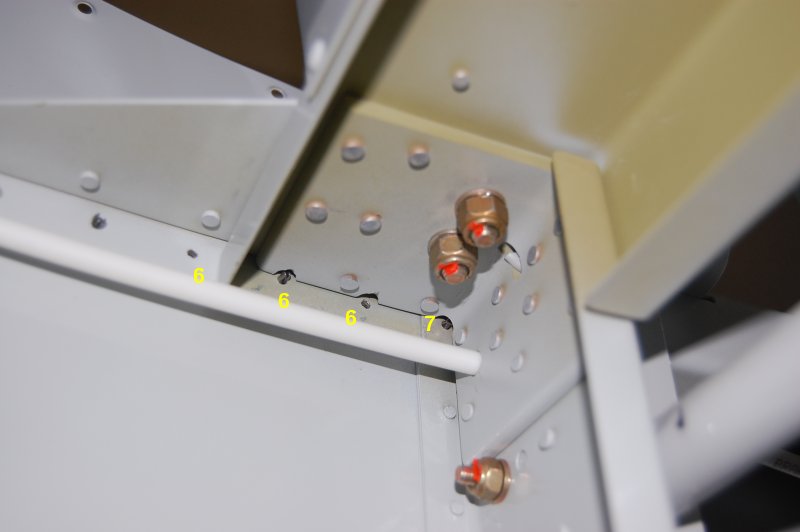

I'm hoping to rivet the front of the F-774 tip up skin and there seems to be no option at this point other than blind rivets. (I cannot buck the 3 inside the frame area)

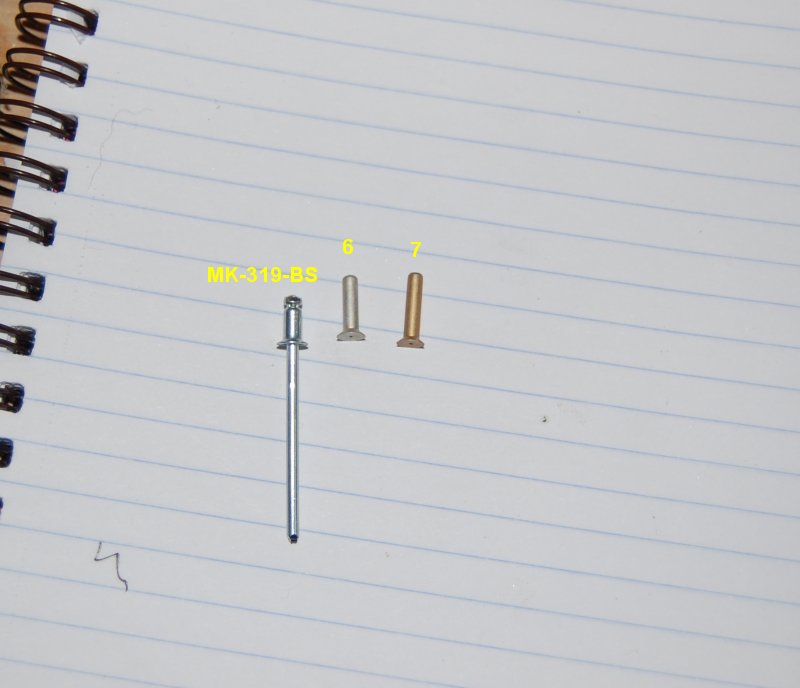

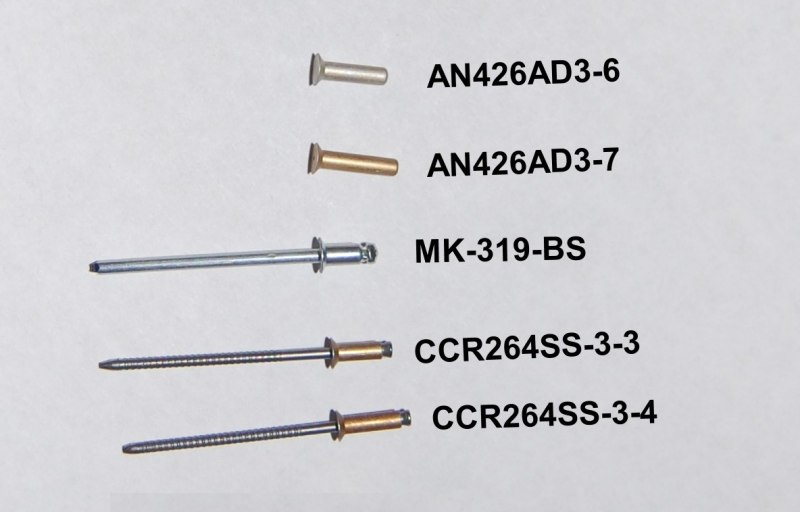

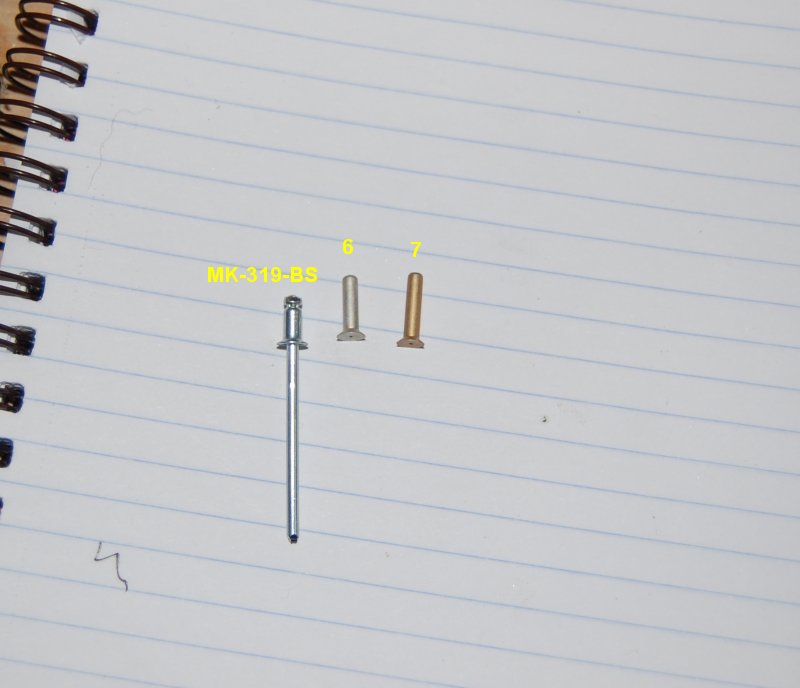

I've seen other planes with blind rivets in this area but where do I find longer ones? I've only seen the MK-319-BS at Vans and it is way too short.

Ideas? Thanks!

I've seen other planes with blind rivets in this area but where do I find longer ones? I've only seen the MK-319-BS at Vans and it is way too short.

Ideas? Thanks!