I like the shape of the Air Trac 500-5 tires for my application. The tread is rounded (a sectional cutaway would have the profile of an inflated inner tube) and I can closely fit my subfairings to them without any pressure points during operation. However, I have recently had two right main landing gear flat tires. The first was on 4-21-12 on the way home from the Hill Country Air Race and the second was on 7-23-12 on the way home from the AirVenture Cup Race. In both cases the middle of the tread was worn through completely in a spot an inch or more in diameter. After the first flat I went to an Air Hawk tire which has a square profile. I installed it and it didn't touch the subfairing. I was a little concerned but after safe operation with the subfairings since I made them and a successful landing I though it would be OK. I was wrong. On a subsequent landing with a little more stress the square sharp cornered flat tread caught the edge of the subfairing and caused significant damage to the subfairing. It required packing modeling clay around the tire and building it up again with new fiberglass. In some unrelated testing I found that the MLG subfairings were good for around 1 kt so I am not going to abandon them. I bought a replacement Air Trac and all seemed well again until the hot landing on 7-23-12 which instantly destroyed it and damage the sub fairing again (ground the bottom off on the concrete).

This obviously will not work for me. I looked in Aircraft Spruce's catalog to see what other tires had a rounded profile. I bought another Specialty Tires & Tubes Air Trac ($62), a Goodyear Flight Special II ($97.85) and a Goodyear Flight Custom III ($164.75) with Air Stop tubes for each (Total $531.60). All three are 6 ply rated.

I intend to come up with a good solution for myself but I thought I would share my findings. The Air Trac tires are very thin from the surface of the tread to the inside of the tire. I think that is an important parameter but I do not have an accurate way to measure it at this time.

I weighed the tires and came up with these numbers:

Air Trac = 4.5 lbs

Flight Special II = 5.4 lbs

Flight Custom III = 6.6 lbs

I photographed them and when they are grouped together the Air Trac is the one on the left and the Flight Custom III is on the right.

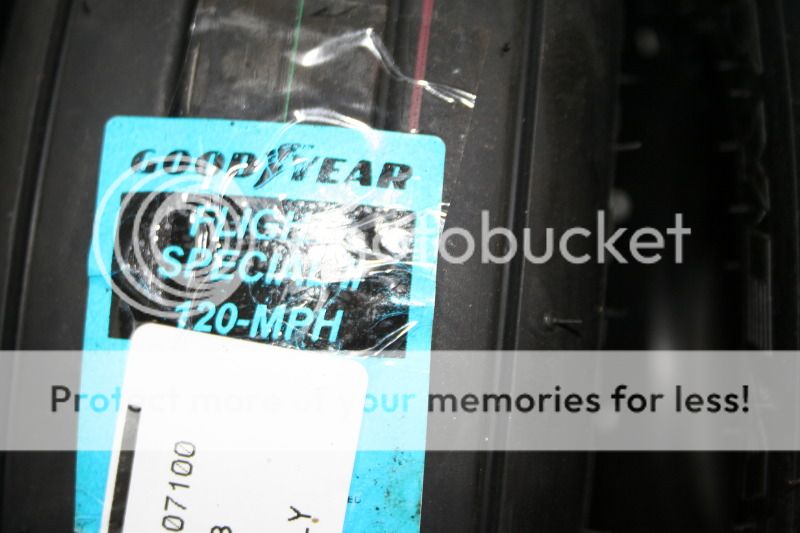

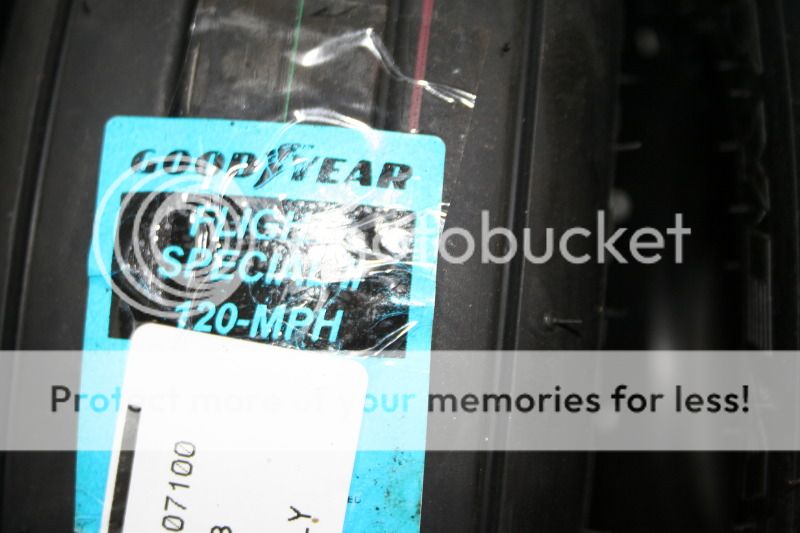

Note the 120 mph marking

Note the 160 mph marking

There is no speed marking on the Air Trac tire that I could see.

That is all the information I have at this time.

Bob Axsom

This obviously will not work for me. I looked in Aircraft Spruce's catalog to see what other tires had a rounded profile. I bought another Specialty Tires & Tubes Air Trac ($62), a Goodyear Flight Special II ($97.85) and a Goodyear Flight Custom III ($164.75) with Air Stop tubes for each (Total $531.60). All three are 6 ply rated.

I intend to come up with a good solution for myself but I thought I would share my findings. The Air Trac tires are very thin from the surface of the tread to the inside of the tire. I think that is an important parameter but I do not have an accurate way to measure it at this time.

I weighed the tires and came up with these numbers:

Air Trac = 4.5 lbs

Flight Special II = 5.4 lbs

Flight Custom III = 6.6 lbs

I photographed them and when they are grouped together the Air Trac is the one on the left and the Flight Custom III is on the right.

Note the 120 mph marking

Note the 160 mph marking

There is no speed marking on the Air Trac tire that I could see.

That is all the information I have at this time.

Bob Axsom

Last edited: