Looking for advice!

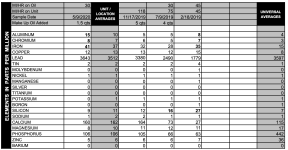

Just had my latest oil report from Blackstone, my metals are trending like the image below.

Note that this last sample was actually from the filter, simply got distracted by hangar visitors and missed my chance to grab some from draining.

170 hours on the engine, not sure why that's not on there. Also, there could have been more oil usage since last check, it says 1.5 but it's probably more like 2-3, but certainly lower than previously.

They commented: "No one thing is terribly out of line, but this is certainly a departure from the way things were going, so it's worth watching. Any high temps? Oil use is down a bit, so maybe metals are just less diluted."

No high oil temps, things seem to be running quite normally.

Being fairly new at what numbers are normal and what to be concerned with I figured I'd get some advice from you good folks

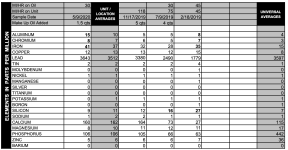

Just had my latest oil report from Blackstone, my metals are trending like the image below.

Note that this last sample was actually from the filter, simply got distracted by hangar visitors and missed my chance to grab some from draining.

170 hours on the engine, not sure why that's not on there. Also, there could have been more oil usage since last check, it says 1.5 but it's probably more like 2-3, but certainly lower than previously.

They commented: "No one thing is terribly out of line, but this is certainly a departure from the way things were going, so it's worth watching. Any high temps? Oil use is down a bit, so maybe metals are just less diluted."

No high oil temps, things seem to be running quite normally.

Being fairly new at what numbers are normal and what to be concerned with I figured I'd get some advice from you good folks

Last edited: