The last major piece of raw material left in our hangar attic for the RV-3 project was the aft top fuselage skin ? the turtle deck. Having run out of excuses and most of the little tasks on the working list being complete, we figured this was a good weekend to give it a go for the initial fitting and drilling. I was shocked when I realized that we had it drilled to all but the F-306 and F-308 bulkheads after about ten people-hours of work! Here are a few of the things we took away from it ? YMMV of course.

1) As an experienced airplane builder now working on an RV-3 once said ?what airplane are these bulkheads supposed to be for anyway?? Laying a straight-edge from the rear bulkheads to the seat back showed that there was no straight line to be had here. Since we had put considerable time into the seat back bulkhead, and the F-309 (just ahead of the aft deck) looked pretty good, we decided to make those the baselines, and make the other two (306, 308) fit.

2) Making the 306 and 308 fit was simple ? we cut the flanges off entirely, and ground away web material until we had clearance between the bulkheads and the skin. The Louise made up some flexible new flanges that we?ll rivet in place (with a perfect fit!) once the skin is firmly attached to the longerons and fore and aft bulkheads. This makes for a smooth, straight skin.

3) Make sure to accurately locate the center line of the aft skin blank. We were just about an eight off, and it made for no extra edge distance along the longeron on one side at the back end. We could have fixed this by sliding the piece aft before we trimmed the front edge ? good lesson for next time.

4) If you have the tail mounted, take it off. Yeah, it looks really nice in the shop with the feathers on, but they are in the way.

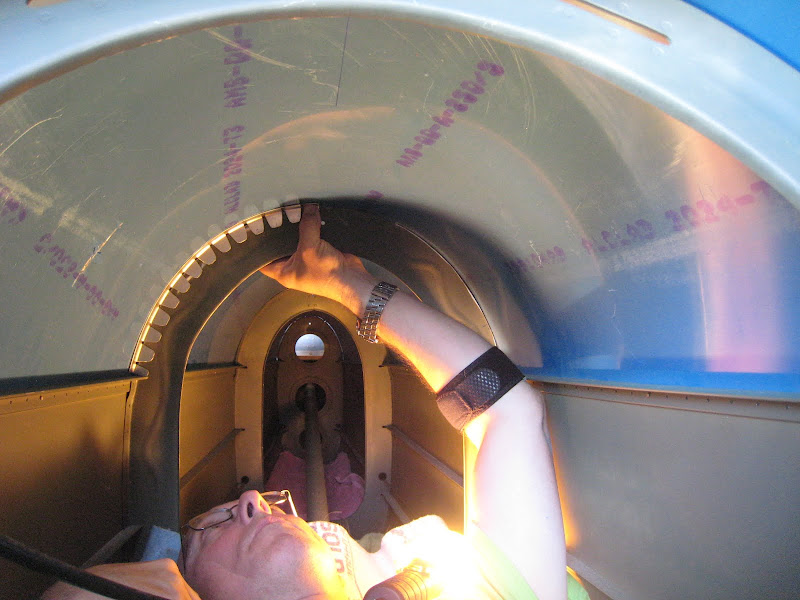

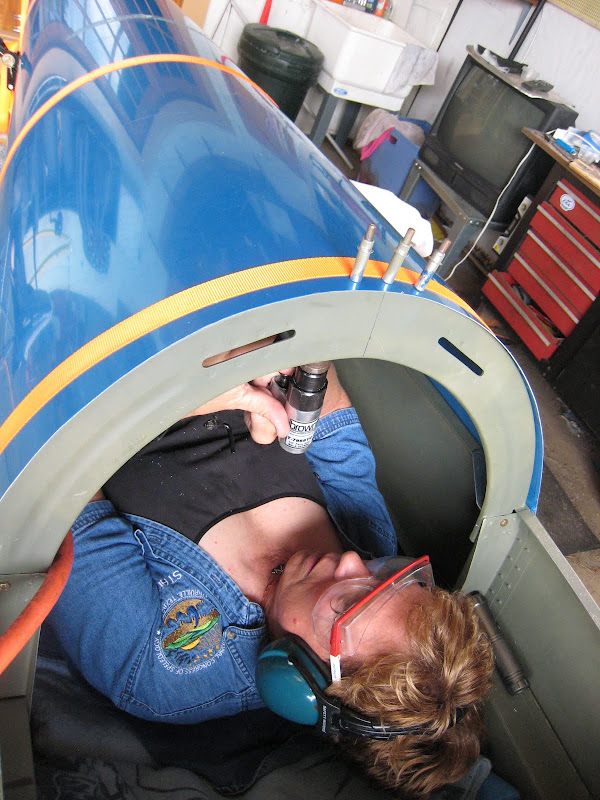

5) A person can actually fit inside the aft fuselage of an RV-3, and do useful work back there! Louise was able to drill all of the longeron rivet holes back to about 6 inches from the F-309 bulkhead before running out of reach. I got those by reaching in through the holes in the aft deck and the -309 to finish the job. Please note ? Louise is an EXPERT cave explorer. It?s her job ? she is a trained professional!

6) Tension straps are a must, as they are for any skin fitting on the fuselage. Be very careful, however, not to start collapsing the side skins! It takes very little tension to do this ? go one ?click? on the cams at a time. You have been warned?.

7) Our drilling pattern was this. We predrilled the holes in the seat back bulkhead, and of course, the longerons. We then match-drilled the front center of the skin to the seat back. This was followed by one hole/cleco in the F-309 at the center to keep the skin straight. We then cinched up the tension straps, and drilled the skin to the longeron holes from the inside, alternating from left to right, one ?bay? at a time. We haven?t drilled the -306 or -309 flanges in place yet ? those should be fairly straightforward.

8) Take out the elevator pushrod and bulkhead. The baggage floor we left in place, then stuff moving blankets in to the ?floor? of each ?bay to bring the driller?s body up above the bottom of the bulkheads. Lots and lots of blankets. Much softer than cave rock?.

9) We cut out some thin plywood doublers for the 306 and 308 bulkheads, and attached them with C-clamps to make them flat. Once you cut off the flanges, they become noodles, and it will be very hard to get them straight and perpendicular to the fuselage for a nice line of rivets.

10) As always, we went slow, questioned everything we were doing, and stopped ourselves from doing something dumb on several occasions. Take nothing for granted!

More pictures at the Picassa Site: http://picasaweb.google.com/DrKarst/JUNIOR#

1) As an experienced airplane builder now working on an RV-3 once said ?what airplane are these bulkheads supposed to be for anyway?? Laying a straight-edge from the rear bulkheads to the seat back showed that there was no straight line to be had here. Since we had put considerable time into the seat back bulkhead, and the F-309 (just ahead of the aft deck) looked pretty good, we decided to make those the baselines, and make the other two (306, 308) fit.

2) Making the 306 and 308 fit was simple ? we cut the flanges off entirely, and ground away web material until we had clearance between the bulkheads and the skin. The Louise made up some flexible new flanges that we?ll rivet in place (with a perfect fit!) once the skin is firmly attached to the longerons and fore and aft bulkheads. This makes for a smooth, straight skin.

3) Make sure to accurately locate the center line of the aft skin blank. We were just about an eight off, and it made for no extra edge distance along the longeron on one side at the back end. We could have fixed this by sliding the piece aft before we trimmed the front edge ? good lesson for next time.

4) If you have the tail mounted, take it off. Yeah, it looks really nice in the shop with the feathers on, but they are in the way.

5) A person can actually fit inside the aft fuselage of an RV-3, and do useful work back there! Louise was able to drill all of the longeron rivet holes back to about 6 inches from the F-309 bulkhead before running out of reach. I got those by reaching in through the holes in the aft deck and the -309 to finish the job. Please note ? Louise is an EXPERT cave explorer. It?s her job ? she is a trained professional!

6) Tension straps are a must, as they are for any skin fitting on the fuselage. Be very careful, however, not to start collapsing the side skins! It takes very little tension to do this ? go one ?click? on the cams at a time. You have been warned?.

7) Our drilling pattern was this. We predrilled the holes in the seat back bulkhead, and of course, the longerons. We then match-drilled the front center of the skin to the seat back. This was followed by one hole/cleco in the F-309 at the center to keep the skin straight. We then cinched up the tension straps, and drilled the skin to the longeron holes from the inside, alternating from left to right, one ?bay? at a time. We haven?t drilled the -306 or -309 flanges in place yet ? those should be fairly straightforward.

8) Take out the elevator pushrod and bulkhead. The baggage floor we left in place, then stuff moving blankets in to the ?floor? of each ?bay to bring the driller?s body up above the bottom of the bulkheads. Lots and lots of blankets. Much softer than cave rock?.

9) We cut out some thin plywood doublers for the 306 and 308 bulkheads, and attached them with C-clamps to make them flat. Once you cut off the flanges, they become noodles, and it will be very hard to get them straight and perpendicular to the fuselage for a nice line of rivets.

10) As always, we went slow, questioned everything we were doing, and stopped ourselves from doing something dumb on several occasions. Take nothing for granted!

More pictures at the Picassa Site: http://picasaweb.google.com/DrKarst/JUNIOR#