Action plan

I spoke with Deene this afternoon. His cowl was close, but not in contact and he had a few ideas. (Actually I've spoken with him a few times now this year.)

Other info of use:

Rhonda at Barrett Precision Engines confirmed the Barrett IO-390 cylinders measure exactly the same as the IO-360A1B6 (Angle valve 200HP)

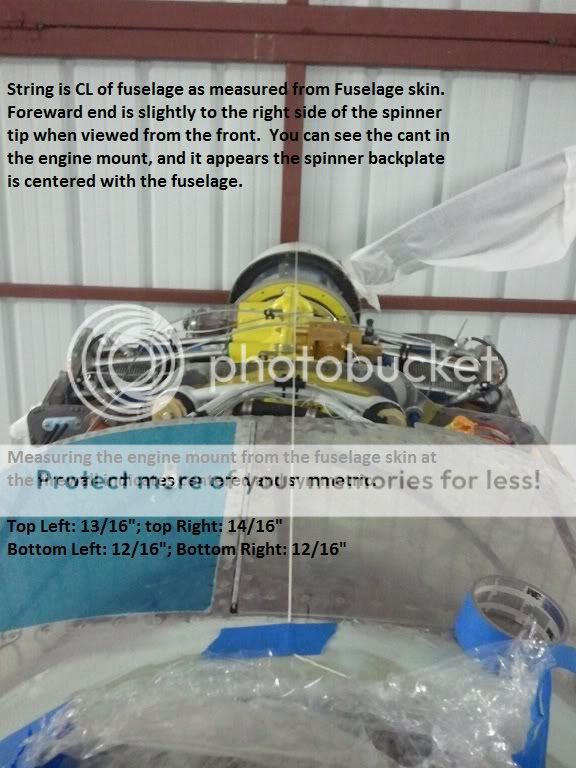

Gus at Vans confirmed my engine appears to be mounted correctly, and confirmed that Cyls #2 and #4 will be very close due to the one point something or other cant in the engine and that some point behind the spinner tip will be centered on the fuselage. (Mine is!)

Will James confirms their cowls are designed for the angle valve 360 (and is compatible with the 390.) BTW, Will has been a pleasure to work with through this, but the best suggestions came from VAF.

I understand the engine rotates on the mount rather than shakes laterally or vertically, so not much clearance is really required. According to Gus, Vans removes core material in their cowls near the rocker cover edges to allow this movement as well.

Every 1/16" of an inch counts, and I'm shooting for 1/4" to be safe.

So here's my action plan. It progresses from least rework to most rework.

1. Firm belief that this cowl is salvageable.

2. Replace horizontal hinges with quarter turn fasteners leaving a gap in the mounting strip at Cyl #2 and Cyl #1

3. Check fit. If it fits with sufficient gap, stop. If not, proceed.

4. Leaving the left side vertical hinge pin in place, pull right side forward slightly.

5. Replace right firewall hinge half with wider piece and create a scarf joint in rear cowl edge, extend with flox and glass strips.

6. Check fit. If it fits with sufficient clearance, stop. If not proceed.

7. Pull both sides out closing the spinner/cowl gap. Fill as required. (It's fiberglass!!!!)

I did some fidgeting at the hangar tonight with adjusting the cowl. I believe the first modification will do the trick and have already removed the horizontal hinge halves from the bottom cowl. The Proseal was three or four (cold) days old and was still pretty soft. After drilling out the rivets and removing the hinge half, a razor blade followed by a cleaning brush and some MEK removed about 95% of the proseal in the area than will be required to bond the quarter turn attachment strips. I'm going to go ahead and replace the top cowl firewall attach hinge with quarter turn fasteners as well.

By the way, after drilling through all this fiberglass, my #40 bit was not doing a great job on the rivet heads. I touched it up with the "Drill Doctor" my dad gave me for Christmas a few years ago and wow, what a difference!!!!!! If you don't have one of these, put it on your Christmas list! (A new bit here and there is cheaper, but if you have several bits of various sizes and use them frequently, it's nice to touch one up while you're working.)

More to come, stay tuned.