guidoism

Member

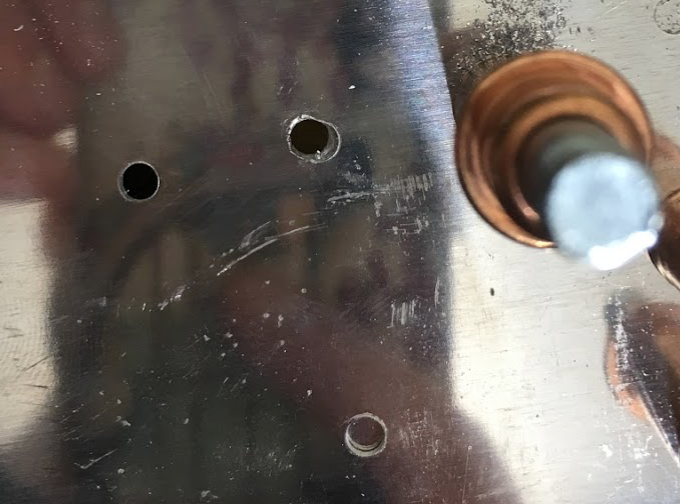

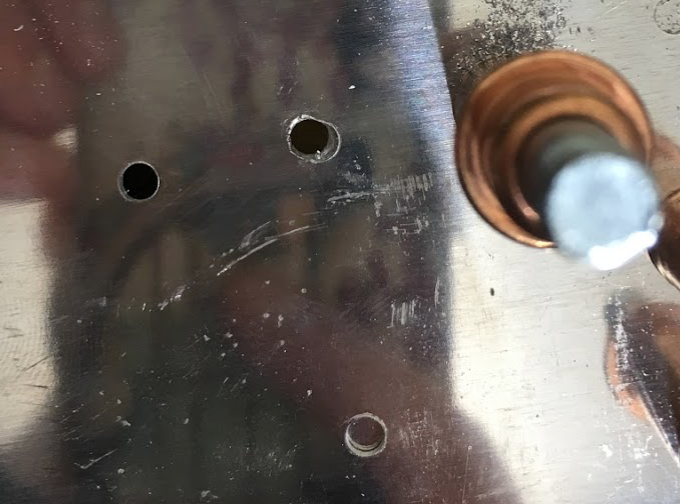

While match drilling the W-707 doubler plates for the rear spar I'm accidentally causing the original holes to widen and become misshapen. I'm assuming this is because I'm not holding the drill straight, or I'm moving it around, or I'm applying pressure laterally. I'm not sure.

Anyways, two questions:

1. Is the biggie in this pic useable or am I going to have to order a new rear spar?

2. How do I match drill without doing this? Do I need to get a drill press?

Anyways, two questions:

1. Is the biggie in this pic useable or am I going to have to order a new rear spar?

2. How do I match drill without doing this? Do I need to get a drill press?