WingsOnWheels

Well Known Member

I dug through old posts and didn't quite find what I was looking for (probably there somewhere though).

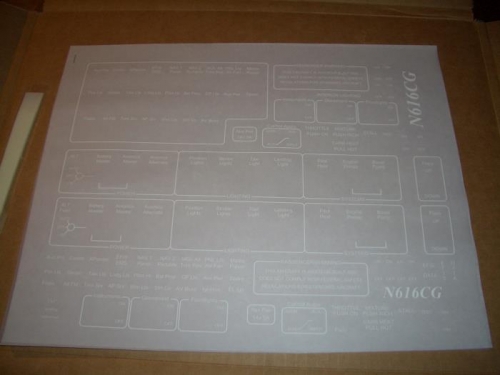

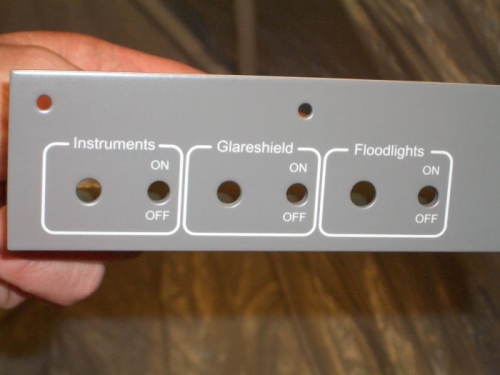

I designed most of my panel cutouts in CAD. As a result, it is pretty easy for me to do the same with the labels. I spoke with Stein about using the water-slide decals, but I would like to be able to tranfer large areas all at once. I have put some snazzy borders and grouping around my switches and since it was cad designed and machine cut it should all line up. With the water-slide I don't think my skill-level is sufficient to move a decal of that size without a screw up.

Taking that all into account I think it would be best to go with dry-transfer decals. However, I don't have much experiance with those. Has anyone applied a large decal? I would do all my switches in one shot and another large one for all my breakers. If you have done something similar, how did it work out for you?

Also, what clearcoats have builders found to work well with the dry transfers? My basecoat will be PPG MTK Urathane and I was planning a low-gloss clear from the same product line over the top of the decals.

Thanks,

I designed most of my panel cutouts in CAD. As a result, it is pretty easy for me to do the same with the labels. I spoke with Stein about using the water-slide decals, but I would like to be able to tranfer large areas all at once. I have put some snazzy borders and grouping around my switches and since it was cad designed and machine cut it should all line up. With the water-slide I don't think my skill-level is sufficient to move a decal of that size without a screw up.

Taking that all into account I think it would be best to go with dry-transfer decals. However, I don't have much experiance with those. Has anyone applied a large decal? I would do all my switches in one shot and another large one for all my breakers. If you have done something similar, how did it work out for you?

Also, what clearcoats have builders found to work well with the dry transfers? My basecoat will be PPG MTK Urathane and I was planning a low-gloss clear from the same product line over the top of the decals.

Thanks,