"Summer" and "winter" are meaningless in terms of analysis. The conditions of interest are engine type, OAT and power setting. Parallel valve engines without piston squirters require less oil cooling. Heat transfer rate is influenced by DeltaT, oil to air. And LOP operation typically reduces both CHT and oil temperature.

180F is perfect, per Lycoming. If you're there, you're fine.

I am NOT there. That's the problem.

I assume your concern is oil temp in the 150's and 160's when OAT and power are both low.

All incorrect assumptions.

All the rest, below, ignored as not relevant to the question. No one said anything about needing 212. No one is talking about a plugged cooler in the summer time.

If someone it telling you oil must reach 212F to boil off water, hand him a physics text.

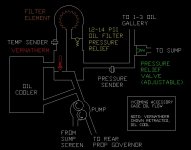

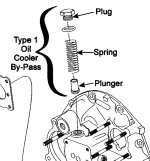

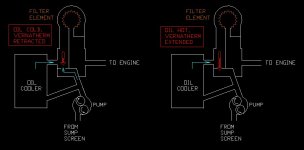

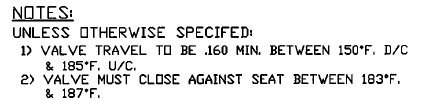

The "always flow in the cooler" design was to accommodate very cold climate operation, and yes, that is rather counter-intuitive given it tends to over cool the oil. The problem was single weight oil in the cooler becoming so viscous in an arctic blast that it would not flow, forming a plug of sorts in the cooler during the initial phase of flight. As oil temp rose, the vernatherm would try to close, but oil couldn't flow through the plugged cooler, and with no flow, it would not warm enough to unplug. That's why a vernatherm has a spring loaded tip (see below). The warming vernatherm will extend to block the bypass, but if the cooler is plugged, the tip will float off the seat at about 15 psi deltaP, allowing continued oil flow to the engine.

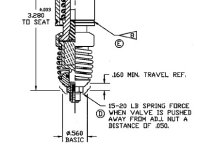

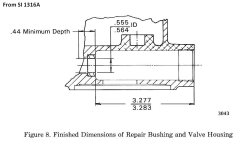

You can gain absolute control of cooler flow rate by removing the vernatherm, then installing a "viscosity valve" spring and plunger assembly in the accessory case, and a 1/4 turn ball valve in one of the cooler lines. The valve can be cockpit controlled. The SI attached below explains how to remove the viscosity valve and replace it with a vernatherm. Just reverse the process.

.

Ok my wondering if the Vernatherm was malfunctioning (or incorrectly set) was based on the possibility that it was letting oil flow to the cooler BEFORE it got to 185. Nothing you've said proves that this isn't happening. But let's not go down that rat hole right now.

So I'll restate the question:

Flying the Northeast, OAT~68, O-360, level at 23 squared, or climbing at 24 squared, no baffle plate on the back side of the oil cooler blocking the air flow, I can't get my oil temps up to 180.

In the Winter, with the baffle plate on, I can't get the oil temps up to 180 in any flight regime.

Oil cooler is at the left hand side of the engine baffle.

This strikes me as unusual. Is it?

Most of the times I see people talking about oil temp problems, they are talking about oil getting too warm - especially in the climb. I've read lots of those.

Is this a common problem (oil temps too low) requiring some alteration the air flow-through in the oil cooler?

I would have thought that given the oil temp sweet spot of 180 , that designs would be such that they would get you in that vicinity. Maybe I'm wrong.

So, flying in the Northeast:

With no baffle on the oil cooler I rarely get my summer flying temps above ~160

With a full plate on the back of the oil cooler I can't get my oil temps up above 160. Usually it's less.

I would have thought that is unusual.