dromuald

Active Member

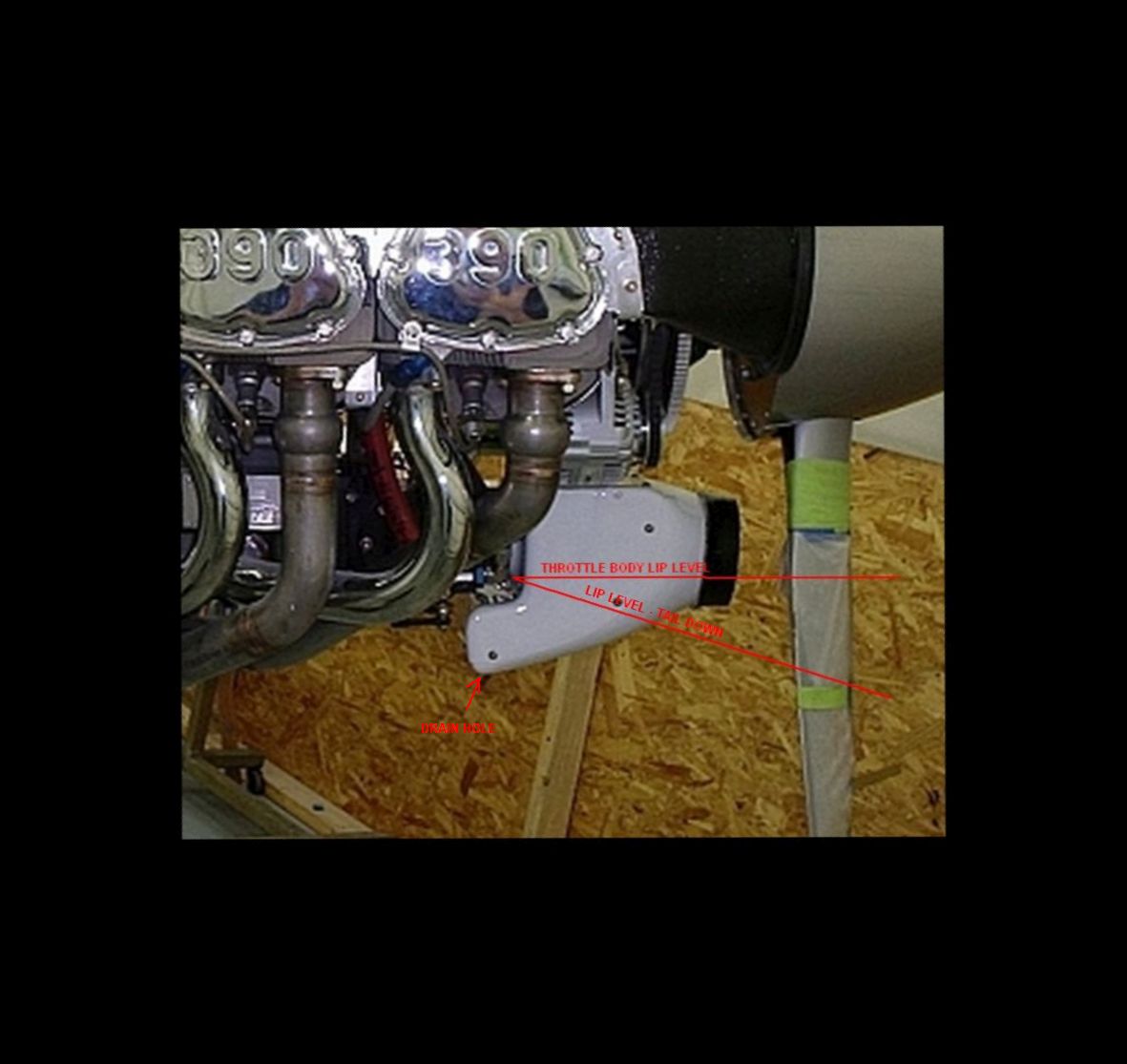

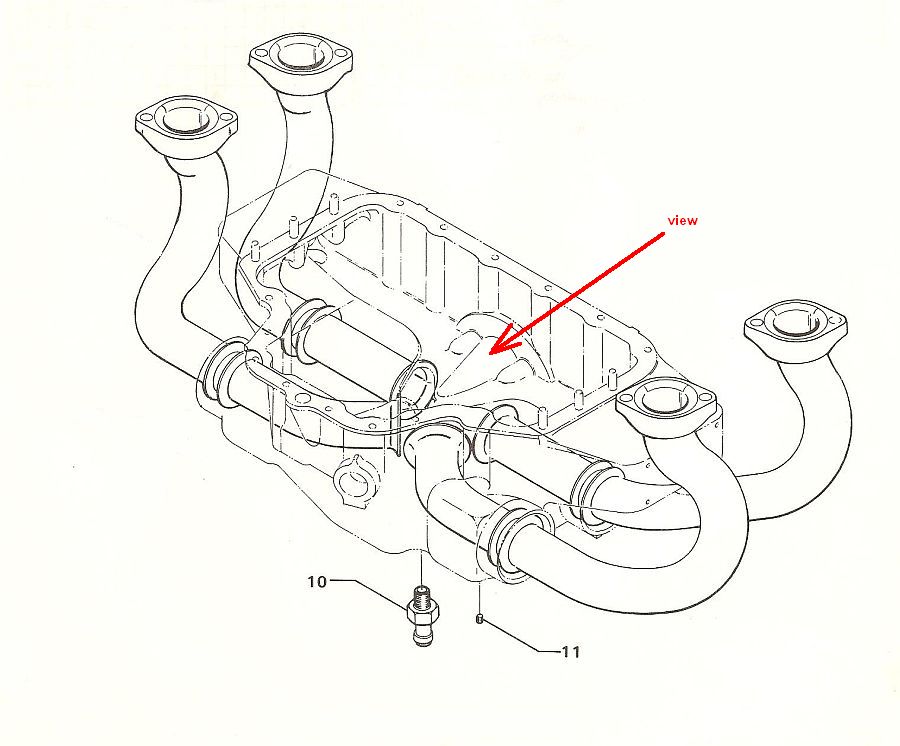

I have an RV 8 with an IO-360 injected motor. I bought the plane from the builder 7 years ago. At my recent condition inspection it was suggested that I install a sniffle valve on the bottom of the intake sump. That port is currently capped off with an AN fitting. This motor has 850 trouble free hours on it over the course of 17 years. My question is this - have I been lucky operating this motor or is the valve not really required. I realize it is used to drain the sump of residual fuel and or oil. If there is no drain does this fuel just get scavenged back into the intake system? I guess my point is why should I mess with success?