LettersFromFlyoverCountry

Well Known Member

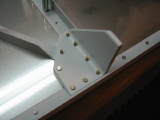

In fabricating the AUX Fuel Pump doubler, I notice on the plans it says to "trim or SCALLOP" the edge of the doubler plate to accomodate hole "C," which I believe is a mixture cable. I can see why,the hole is right on the edge of the doubler plate. But I've never seen the term "scallop" before. What does it mean in this instance." I assume it involves filing a hole large enough to compensate for the cable. But I don't know what the cable size is here so I'm not sure how much of a trim to make.

Also, where the recess is concerned, I guess you have the option of installing it with the flange on the forward side, or "hidden" under the stiffeners on the aft side. Wondering if there's a conventional wisdom for this that I should be considering. It doesn't seem to make any difference.

Also, where the recess is concerned, I guess you have the option of installing it with the flange on the forward side, or "hidden" under the stiffeners on the aft side. Wondering if there's a conventional wisdom for this that I should be considering. It doesn't seem to make any difference.