Well, I finished the wing spar bolts, so the wings are finalized, and the flaps are trimmed and hung. I will cut the fuselage and connect the actuators tommorrow.

Anyone who has ever done these bolts on an RV-6 knows that this is a big step to get behind you, it took me days.

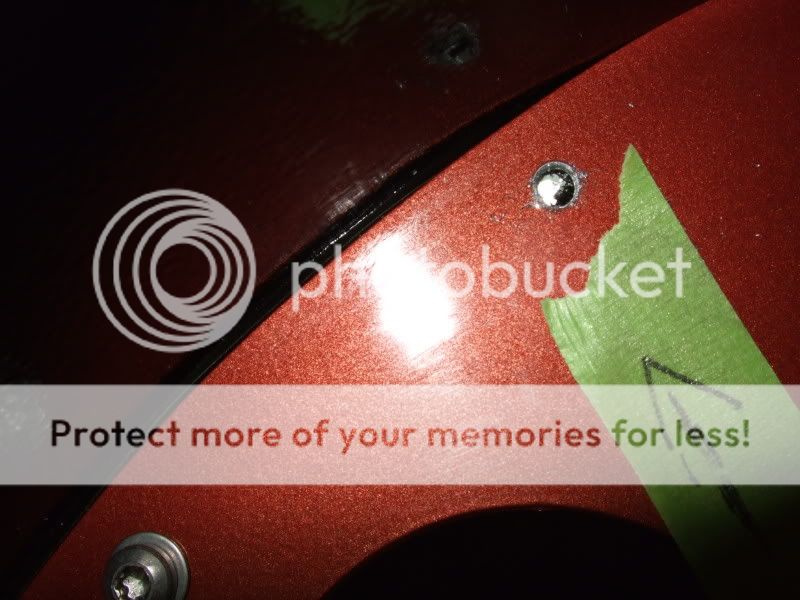

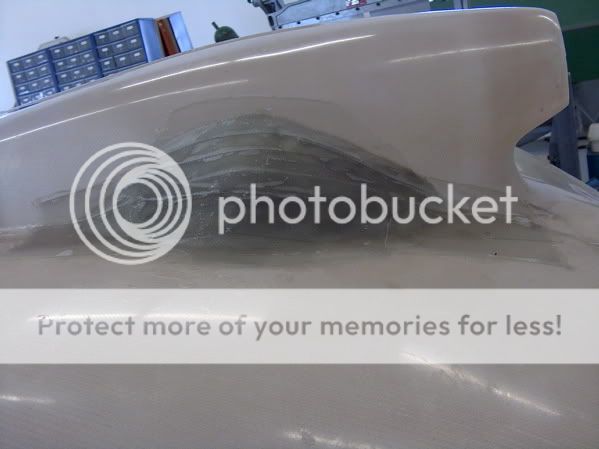

Here is what the flap looks like on the wing.

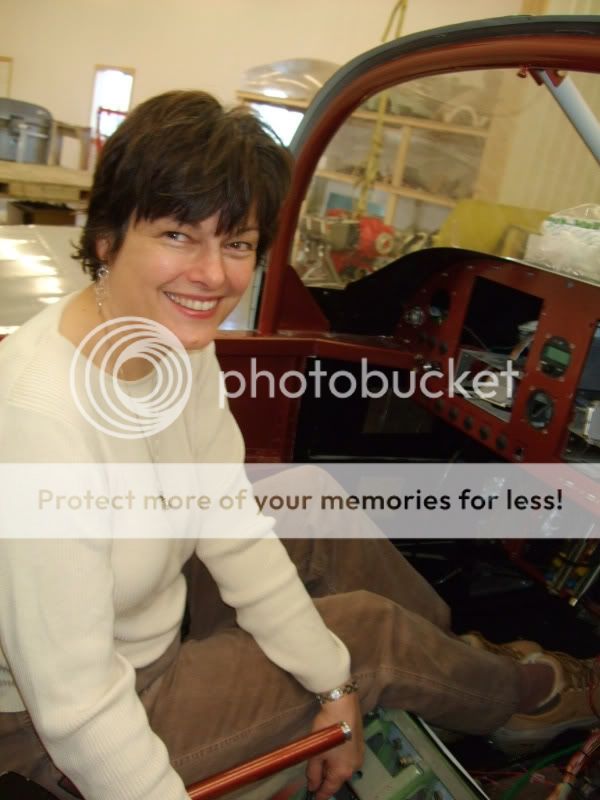

Here is an overall shot of the plane in it's current state of build. Please not that there is a restraining bolt that goes on the nosewheel before first flight, so it cannot interfere with the prop like in the position shown here. We take it off to make the plane easier to move around the shop.

The engine wiring is done. Firewall forward-wise, I need to finish the alternate air on the airbox. run the throttle and prop cables, plumb the cabin air; and glue the trim rings to the plenum.

There are a lot of odds and ends left to do, but it is feeling like I am on the homestretch.

Hans

Anyone who has ever done these bolts on an RV-6 knows that this is a big step to get behind you, it took me days.

Here is what the flap looks like on the wing.

Here is an overall shot of the plane in it's current state of build. Please not that there is a restraining bolt that goes on the nosewheel before first flight, so it cannot interfere with the prop like in the position shown here. We take it off to make the plane easier to move around the shop.

The engine wiring is done. Firewall forward-wise, I need to finish the alternate air on the airbox. run the throttle and prop cables, plumb the cabin air; and glue the trim rings to the plenum.

There are a lot of odds and ends left to do, but it is feeling like I am on the homestretch.

Hans

Last edited: