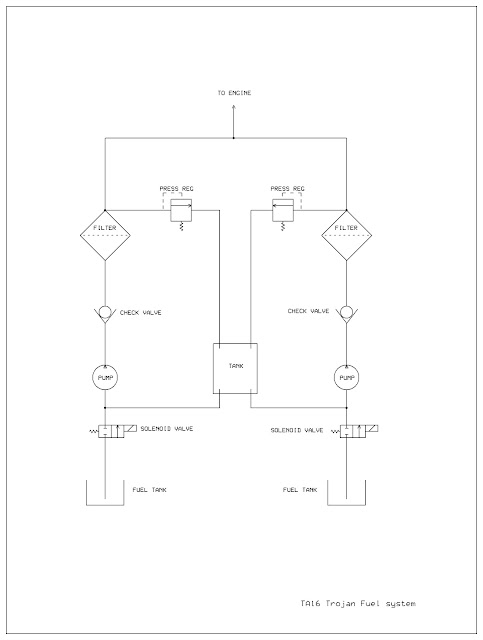

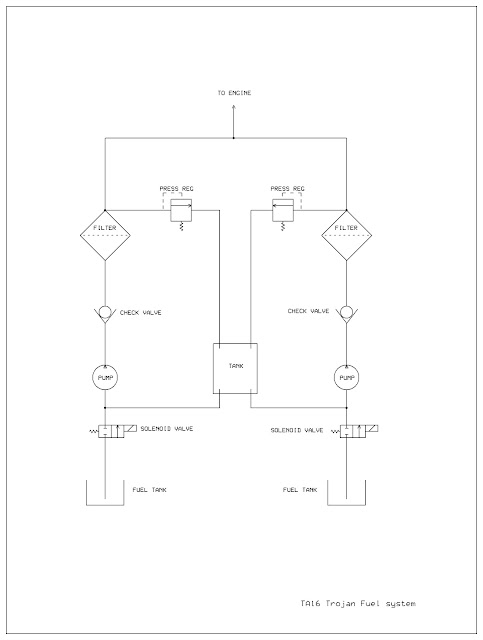

I hope it is alright to post here, even though the aircraft not a Van's, but is a Thurston-TA-16 with a LS1 fuel injected engine. VansAirforce is where all of the most knowledgeable people hang out. A friend of mine is building the TA16, which is at the stage where it is starting to look like an airplane. Below is a diagram of his fuel system which is already installed. I drew the filter and pressure regulator separately, but they are actually combined in one unit. The tank in the center holds about a quart. My friend calls it an accumulator, but I think that it is just a large-volume 4-way "T". I have concerns about the consequences of a pressure regulator failing. Is there a problem with turning on both solenoid valves but only one fuel pump? Comments, suggestions and criticism are welcome. PDF Version - ExpressSch Version