Davepar

Well Known Member

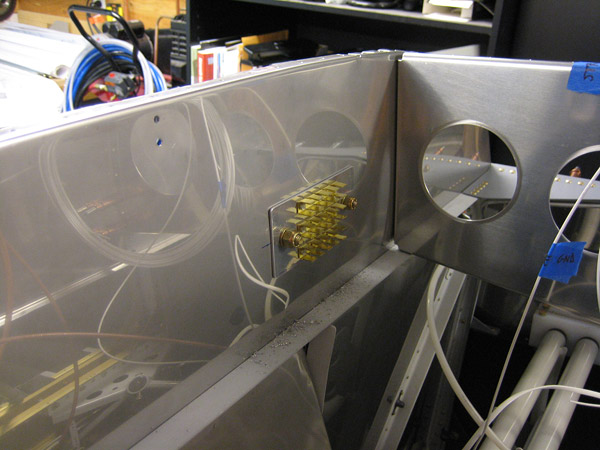

I made my own ground block by riveting the tabs that SteinAir sells to a piece of spare .063 sheet aluminum. Total cost $3. I was pretty happy with myself until I started to wonder if this was such a good idea. Will the brass tabs and aluminum react with each other? Should I just throw some dielectric grease on there? I ran across Amit's article which looks like a very similar approach.

Picture (kind of fuzzy):

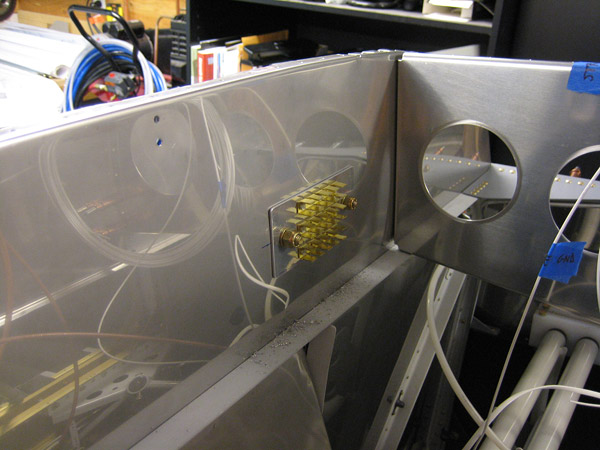

Installed:

Dave

Picture (kind of fuzzy):

Installed:

Dave